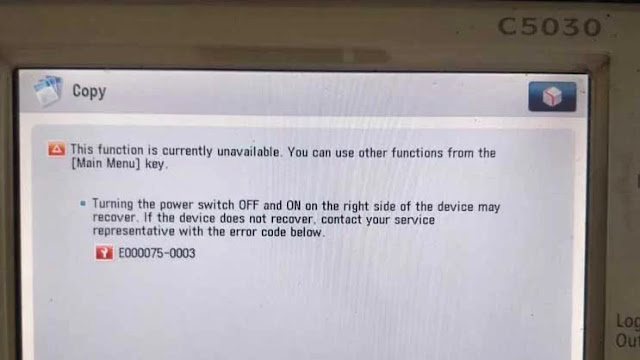

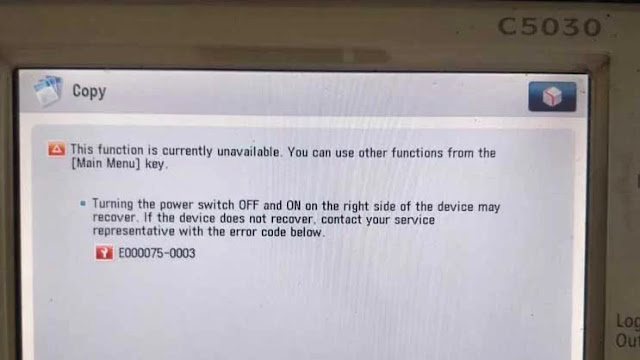

The following instructions describe how to reset E00075 for a Canon IR advance C5035, C5045, C5251, C5245, C5250, copier machine. We are sharing a few methods to fix the error, so check them one by one until it gets solved…….

|

| How to clear E000075 error Code Canon IR advance C5045, C5251 |

These instructions describe the error code E075 solution for a Canon ImageRunner copier machine. The following instructions describe how to reset E00075 for a Canon IR advance C5035, C5045, C5251, C5245, C5250, copier machine. We are sharing a few methods to fix the error, so check them one by one until it gets solved.

Meaning of the Error Code:

The E075 error code refers to the ITB belt shifting front to the rear of the machine and cannot compensate. Two causes will make this happen. Fast is the machine that is not level. Secant is the uneven thickness of the ITB belt from front to rear.

Maintenance sign means that the copier needs to be well serviced or something has to be replaced like Consumables such as drum, blade, fuser rollers, and developer, etc. If you are sure that you replaced the correct parts or the machine doesn’t need to replace any part, then you can continue to clear the sign.

How to fix E075 Error Code:

To resolve this issue, first, observe the ITB Position value of displacement in service mode under Copier > Display > Misc. > ITB-POS. The range is between -300 to 450. If the value is very close to the high end or low end, perform the following:

- Check to make sure that the machine is level.

- After levelling the machine, run Copier > Function > MISC-P > ITB-INT in service mode.

- Check Copier > Display > MISC > ITB-POS again to make sure the value is approximately within the mid-range.

- If the value in step c is not within mid-range, remove the ITB belt and reverse it from front to rear and repeat the prior steps again.

If you find your parts, then replace the parts and error still remains, after automatically reset the error code. If the error is still showing even after the above solutions, then you have no choice other than calling Canon service technician.

I hope this was helpful, don’t forget to share it via any of the share buttons on this page are highly welcomed as well.

The fuser film needs replacing

Was this post helpful?

thumb_up

thumb_down

The E075 error code refers to the ITB belt shifting front to rear of the machine and can not compensate. There are two causes that will make this happen.

a) The machine that is not level

b) Uneven thickness of the ITB belt from front to rear.

To resolve this issue, first observe the ITB Position value of displacement in service mode under Copier > Display > Misc > ITB-POS. The range is between -300 to 450. If the value is very close to the high end or low end, perform the following:

a) Check to make sure that the machine is level.

b) After leveling the machine, run Copier > Function > MISC-P > ITB-INT in service mode

c) Check Copier > Display > MISC > ITB-POS again to make sure the value is approximately within the mid range

d) If the value in step c is not within mid range, remove the ITB belt and reverse it from front to rear and repeat the prior steps again.

0 of 1 found this helpful

thumb_up

thumb_down

-

12-11-2013

#1

Greeting,

I am not a trained tech on the Canon C5051 but we have one on which we frequently get an E0075 0003 error. From the error code, it is my understanding that the transfer belt is walking to it’s full displacement and then sending a E0075 0003 error and the machine stopped, thereby avoiding damaging the belt. After the belt is manually «walked» back into postion, all is well for a little while and then it occurs again.I had a tech in the past tell me that this can occur if the machine is not on the level. So, my questions are 1) is this correct 2) does the machine have a built in method in which a tech can adjust the machine to level, or does one have to have a physical level and adjust the feet.

Since I am not a tech, I cannot get any information out of Canon and we are midstream changing to a new service people so our old tech is gone. I really want to know if I should keep barking at them about checking the level on the machine, or if I am totally out of line to suggest that they adjust it. Thanks for your insight.

Last edited by Nobilis; 12-11-2013 at 03:25 PM.

Reason: spelling

-

12-11-2013

#2

Trusted Tech

50+ Posts

- Rep Power

- 22

Re: E0075 0003

I’m not familiar with that particular problem but I do know that as a rule all copiers should be fairly close to level. A very effective and yet simple way to test this is to put a steel bearing in the middle of the copy glass surface, this is the place where you lay a piece of paper that will be copied. If the bearing stays where you’ve placed it, then the copier is level. I’ve used glass marbles as well, but they will not be as precise as a single steel ball bearing, none the less for this test it’s probably fine.

Ron

-

12-12-2013

#3

Re: E0075 0003

December 1, 2011

Product : imageRUNNER ADVANCE C5030 / C5035 / C5045 / C5051

Title : E075 — 0003

Problem : The machine displayed an error code of E075 with a sub code of 0003. This indicates an error in full displacement of the ITB to the rear side.

Solution : Behind the ITB motor there is a silver bracket with two silver screws. This bracket affects the tracking of the belt. Remove the ITB motor. Loosen the two screws on the bracket and adjust the bracket 1mm at a time until the belt stops tracking off. The location of the bracket and the screws are shown below.

Canon USA, Inc. Engineering Services & Solutions Division

**Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

12-12-2013

#4

Re: E0075 0003

August 24, 2010

Product : imageRUNNER ADVANCE C5030 / C5035 / C5045 / C5051

Title : E075 error code on the imageRUNNER ADVANCE C5051 Series

Problem : E075 error code on the imageRUNNER ADVANCE C5051 Series

Solution : The E075 error code refers to the ITB belt shifting front to rear of the machine and can not compensate. There are two causes that will make this happen. a) The machine that is not level b) Uneven thickness of the ITB belt from front to rear.

To resolve this issue, first observe the ITB Position value of displacement in service mode under Copier > Display > Misc > ITB-POS. The range is between -300 to +450. If the value is very close to the high end or low end, perform the following:

a) Check to make sure that the machine is level. b) After leveling the machine, run Copier > Function > MISC-P > ITB-INT in service mode c) Check Copier > Display > MISC > ITB-POS again to make sure the value is approximately within the mid range d) If the value in step c is not within mid range, remove the ITB belt and reverse it from front to rear and repeat the prior steps again.

Canon USA, Inc. Engineering Services & Solutions Division

**Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

12-12-2013

#5

Re: E0075 0003

May 04, 2011

Product : imageRUNNER ADVANCE C5030 / C5035 / C5045 / C5051

Title : E075-0000 Error Code

Error : E075-0000 Error Code

Workaround : If you have a E075-0000 code, check the Secondary Inner Roller (FC8-4402-000) and the Secondary Transfer bushing Holder (FL3-1109-000). Check to see if the roller shaft ends are worn down. This could be either on the front or rear side. If the shaft or bushing holders are worn, this could cause the belt to shift either towards the front or back of the ITB assembly causing a E075 error code.

Canon USA, Inc. Engineering Services & Solutions Division

**Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

12-12-2013

#6

Re: E0075 0003

Originally Posted by Ron314

I’m not familiar with that particular problem but I do know that as a rule all copiers should be fairly close to level. A very effective and yet simple way to test this is to put a steel bearing in the middle of the copy glass surface, this is the place where you lay a piece of paper that will be copied. If the bearing stays where you’ve placed it, then the copier is level. I’ve used glass marbles as well, but they will not be as precise as a single steel ball bearing, none the less for this test it’s probably fine.

Ron

Ron, I ran your test with a glass ball that I had on hand and it accelerated forward off the machine. I relayed this to the repair techs to ask that they make sure to level the machine for us in such a way that we won’t inadvertently shift it.

-

12-12-2013

#7

Re: E0075 0003

Originally Posted by teckat

August 24, 2010

Product : imageRUNNER ADVANCE C5030 / C5035 / C5045 / C5051

Title : E075 error code on the imageRUNNER ADVANCE C5051 Series

Problem : E075 error code on the imageRUNNER ADVANCE C5051 Series

Solution : The E075 error code refers to the ITB belt shifting front to rear of the machine and can not compensate. There are two causes that will make this happen. a) The machine that is not level b) Uneven thickness of the ITB belt from front to rear.

To resolve this issue, first observe the ITB Position value of displacement in service mode under Copier > Display > Misc > ITB-POS. The range is between -300 to +450. If the value is very close to the high end or low end, perform the following:

a) Check to make sure that the machine is level. b) After leveling the machine, run Copier > Function > MISC-P > ITB-INT in service mode c) Check Copier > Display > MISC > ITB-POS again to make sure the value is approximately within the mid range d) If the value in step c is not within mid range, remove the ITB belt and reverse it from front to rear and repeat the prior steps again.

Canon USA, Inc. Engineering Services & Solutions Division

Thanks for the information Teckat. I looked at the codes and the machine was within the displacement range. So, I decided to relay to the Techs about the machine not being on the level and trust that they will take that into account when they come out to service the unit. I appreciate the pointers from everyone on this so I can speak a bit more intelligently with our reps.

-

12-12-2013

#8

Re: E0075 0003

Originally Posted by Nobilis

Thanks for the information Teckat. I looked at the codes and the machine was within the displacement range. So, I decided to relay to the Techs about the machine not being on the level and trust that they will take that into account when they come out to service the unit. I appreciate the pointers from everyone on this so I can speak a bit more intelligently with our reps.

—————————

your welcome

there are installation procedures that need to be followed on all Canon Printers, sadly not all techs are trained on the products they service—-

the Function below is in the install procedure check for IRADC5051ITB.JPG

COPIER > FUNCTION > MISC-P ITB-INIT

Initial adjustment of ITB Steering

Level.1 =Details To make initial adjustment of reference position for the ITB Steering at initial installation or replacement of the ITB-related service parts.

Use cases — -At installation

—When replacing the ITB-related service parts

Adj/set/operate method = Select the item, and then press OK key.

Caution = Be sure to close all covers before execution.

Display/adj/set range In processing: ACTIVE, At normal termination: OK, At abnormal termination: NG

Required time Approx. 1 minute

———————————————————————————————————————-

Related service mode/ COPIER> DISPLAY> MISC> ITB-POS

Display of ITB steering reference position

Level.1 Details To display the steering reference position of ITB.

Use case = At initial installation (after execution of COPIER> FUNCTION>MISC-P> ITB-INIT)

Adj/set/operate method = N/A (display only)

Display/adj/set range -580 to 580

Unit = 1 pulse

Appropriate target value -300 to 450

Related service mode COPIER> FUNCTION> MISC-P> ITB-INIT

see attached pdf

**Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

12-12-2013

#9

Technician

- Rep Power

- 29

Re: E0075 0003

[QUOTE=teckat;393590]—————————

your welcome

there are installation procedures that need to be followed on all Canon Printers, sadly not all techs are trained on the products they service—-

the Function below is in the install procedure check for IRADC5051ITB.JPG

COPIER > FUNCTION > MISC-P ITB-INIT

Initial adjustment of ITB Steering

Level.1 =Details To make initial adjustment of reference position for the ITB Steering at initial installation or replacement of the ITB-related service parts.

Use cases — -At installation

—When replacing the ITB-related service parts

Adj/set/operate method = Select the item, and then press OK key.

Caution = Be sure to close all covers before execution.

Display/adj/set range In processing: ACTIVE, At normal termination: OK, At abnormal termination: NG

Required time Approx. 1 minute

———————————————————————————————————————-

Related service mode/ COPIER> DISPLAY> MISC> ITB-POS

Display of ITB steering reference position

Level.1 Details To display the steering reference position of ITB.

Use case = At initial installation (after execution of COPIER> FUNCTION>MISC-P> ITB-INIT)

Adj/set/operate method = N/A (display only)

Display/adj/set range -580 to 580

Unit = 1 pulse

Appropriate target value -300 to 450

Related service mode COPIER> FUNCTION> MISC-P> ITB-INIT

see attached pdf

Hi

my problem

iRAC5235i changed ITB unit for new one ,after ITB init received E 075-003.Counter 102:25000.any idea?

-

12-12-2013

#10

Re: E0075 0003

Is printer level ?

What is reading on display ?**Knowledge is time consuming, exhausting and costly for a trained Tech.**

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

The fuser film needs replacing

Was this post helpful?

thumb_up

thumb_down

The E075 error code refers to the ITB belt shifting front to rear of the machine and can not compensate. There are two causes that will make this happen.

a) The machine that is not level

b) Uneven thickness of the ITB belt from front to rear.

To resolve this issue, first observe the ITB Position value of displacement in service mode under Copier > Display > Misc > ITB-POS. The range is between -300 to 450. If the value is very close to the high end or low end, perform the following:

a) Check to make sure that the machine is level.

b) After leveling the machine, run Copier > Function > MISC-P > ITB-INT in service mode

c) Check Copier > Display > MISC > ITB-POS again to make sure the value is approximately within the mid range

d) If the value in step c is not within mid range, remove the ITB belt and reverse it from front to rear and repeat the prior steps again.

0 of 1 found this helpful

thumb_up

thumb_down

The following instructions describe how to reset E00075 for a Canon IR advance C5035, C5045, C5251, C5245, C5250, copier machine. We are sharing a few methods to fix the error, so check them one by one until it gets solved…….

|

| How to clear E000075 error Code Canon IR advance C5045, C5251 |

These instructions describe the error code E075 solution for a Canon ImageRunner copier machine. The following instructions describe how to reset E00075 for a Canon IR advance C5035, C5045, C5251, C5245, C5250, copier machine. We are sharing a few methods to fix the error, so check them one by one until it gets solved.

Meaning of the Error Code:

The E075 error code refers to the ITB belt shifting front to the rear of the machine and cannot compensate. Two causes will make this happen. Fast is the machine that is not level. Secant is the uneven thickness of the ITB belt from front to rear.

Maintenance sign means that the copier needs to be well serviced or something has to be replaced like Consumables such as drum, blade, fuser rollers, and developer, etc. If you are sure that you replaced the correct parts or the machine doesn’t need to replace any part, then you can continue to clear the sign.

How to fix E075 Error Code:

To resolve this issue, first, observe the ITB Position value of displacement in service mode under Copier > Display > Misc. > ITB-POS. The range is between -300 to 450. If the value is very close to the high end or low end, perform the following:

- Check to make sure that the machine is level.

- After levelling the machine, run Copier > Function > MISC-P > ITB-INT in service mode.

- Check Copier > Display > MISC > ITB-POS again to make sure the value is approximately within the mid-range.

- If the value in step c is not within mid-range, remove the ITB belt and reverse it from front to rear and repeat the prior steps again.

If you find your parts, then replace the parts and error still remains, after automatically reset the error code. If the error is still showing even after the above solutions, then you have no choice other than calling Canon service technician.

I hope this was helpful, don’t forget to share it via any of the share buttons on this page are highly welcomed as well.

-

12-11-2013

#1

Greeting,

I am not a trained tech on the Canon C5051 but we have one on which we frequently get an E0075 0003 error. From the error code, it is my understanding that the transfer belt is walking to it’s full displacement and then sending a E0075 0003 error and the machine stopped, thereby avoiding damaging the belt. After the belt is manually «walked» back into postion, all is well for a little while and then it occurs again.I had a tech in the past tell me that this can occur if the machine is not on the level. So, my questions are 1) is this correct 2) does the machine have a built in method in which a tech can adjust the machine to level, or does one have to have a physical level and adjust the feet.

Since I am not a tech, I cannot get any information out of Canon and we are midstream changing to a new service people so our old tech is gone. I really want to know if I should keep barking at them about checking the level on the machine, or if I am totally out of line to suggest that they adjust it. Thanks for your insight.

Last edited by Nobilis; 12-11-2013 at 03:25 PM.

Reason: spelling

-

12-11-2013

#2

Trusted Tech

50+ Posts

- Rep Power

- 21

Re: E0075 0003

I’m not familiar with that particular problem but I do know that as a rule all copiers should be fairly close to level. A very effective and yet simple way to test this is to put a steel bearing in the middle of the copy glass surface, this is the place where you lay a piece of paper that will be copied. If the bearing stays where you’ve placed it, then the copier is level. I’ve used glass marbles as well, but they will not be as precise as a single steel ball bearing, none the less for this test it’s probably fine.

Ron

-

12-12-2013

#3

Re: E0075 0003

December 1, 2011

Product : imageRUNNER ADVANCE C5030 / C5035 / C5045 / C5051

Title : E075 — 0003

Problem : The machine displayed an error code of E075 with a sub code of 0003. This indicates an error in full displacement of the ITB to the rear side.

Solution : Behind the ITB motor there is a silver bracket with two silver screws. This bracket affects the tracking of the belt. Remove the ITB motor. Loosen the two screws on the bracket and adjust the bracket 1mm at a time until the belt stops tracking off. The location of the bracket and the screws are shown below.

Canon USA, Inc. Engineering Services & Solutions Division

**Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

12-12-2013

#4

Re: E0075 0003

August 24, 2010

Product : imageRUNNER ADVANCE C5030 / C5035 / C5045 / C5051

Title : E075 error code on the imageRUNNER ADVANCE C5051 Series

Problem : E075 error code on the imageRUNNER ADVANCE C5051 Series

Solution : The E075 error code refers to the ITB belt shifting front to rear of the machine and can not compensate. There are two causes that will make this happen. a) The machine that is not level b) Uneven thickness of the ITB belt from front to rear.

To resolve this issue, first observe the ITB Position value of displacement in service mode under Copier > Display > Misc > ITB-POS. The range is between -300 to +450. If the value is very close to the high end or low end, perform the following:

a) Check to make sure that the machine is level. b) After leveling the machine, run Copier > Function > MISC-P > ITB-INT in service mode c) Check Copier > Display > MISC > ITB-POS again to make sure the value is approximately within the mid range d) If the value in step c is not within mid range, remove the ITB belt and reverse it from front to rear and repeat the prior steps again.

Canon USA, Inc. Engineering Services & Solutions Division

**Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

12-12-2013

#5

Re: E0075 0003

May 04, 2011

Product : imageRUNNER ADVANCE C5030 / C5035 / C5045 / C5051

Title : E075-0000 Error Code

Error : E075-0000 Error Code

Workaround : If you have a E075-0000 code, check the Secondary Inner Roller (FC8-4402-000) and the Secondary Transfer bushing Holder (FL3-1109-000). Check to see if the roller shaft ends are worn down. This could be either on the front or rear side. If the shaft or bushing holders are worn, this could cause the belt to shift either towards the front or back of the ITB assembly causing a E075 error code.

Canon USA, Inc. Engineering Services & Solutions Division

**Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

12-12-2013

#6

Re: E0075 0003

Originally Posted by Ron314

I’m not familiar with that particular problem but I do know that as a rule all copiers should be fairly close to level. A very effective and yet simple way to test this is to put a steel bearing in the middle of the copy glass surface, this is the place where you lay a piece of paper that will be copied. If the bearing stays where you’ve placed it, then the copier is level. I’ve used glass marbles as well, but they will not be as precise as a single steel ball bearing, none the less for this test it’s probably fine.

Ron

Ron, I ran your test with a glass ball that I had on hand and it accelerated forward off the machine. I relayed this to the repair techs to ask that they make sure to level the machine for us in such a way that we won’t inadvertently shift it.

-

12-12-2013

#7

Re: E0075 0003

Originally Posted by teckat

August 24, 2010

Product : imageRUNNER ADVANCE C5030 / C5035 / C5045 / C5051

Title : E075 error code on the imageRUNNER ADVANCE C5051 Series

Problem : E075 error code on the imageRUNNER ADVANCE C5051 Series

Solution : The E075 error code refers to the ITB belt shifting front to rear of the machine and can not compensate. There are two causes that will make this happen. a) The machine that is not level b) Uneven thickness of the ITB belt from front to rear.

To resolve this issue, first observe the ITB Position value of displacement in service mode under Copier > Display > Misc > ITB-POS. The range is between -300 to +450. If the value is very close to the high end or low end, perform the following:

a) Check to make sure that the machine is level. b) After leveling the machine, run Copier > Function > MISC-P > ITB-INT in service mode c) Check Copier > Display > MISC > ITB-POS again to make sure the value is approximately within the mid range d) If the value in step c is not within mid range, remove the ITB belt and reverse it from front to rear and repeat the prior steps again.

Canon USA, Inc. Engineering Services & Solutions Division

Thanks for the information Teckat. I looked at the codes and the machine was within the displacement range. So, I decided to relay to the Techs about the machine not being on the level and trust that they will take that into account when they come out to service the unit. I appreciate the pointers from everyone on this so I can speak a bit more intelligently with our reps.

-

12-12-2013

#8

Re: E0075 0003

Originally Posted by Nobilis

Thanks for the information Teckat. I looked at the codes and the machine was within the displacement range. So, I decided to relay to the Techs about the machine not being on the level and trust that they will take that into account when they come out to service the unit. I appreciate the pointers from everyone on this so I can speak a bit more intelligently with our reps.

—————————

your welcome

there are installation procedures that need to be followed on all Canon Printers, sadly not all techs are trained on the products they service—-

the Function below is in the install procedure check for IRADC5051ITB.JPG

COPIER > FUNCTION > MISC-P ITB-INIT

Initial adjustment of ITB Steering

Level.1 =Details To make initial adjustment of reference position for the ITB Steering at initial installation or replacement of the ITB-related service parts.

Use cases — -At installation

—When replacing the ITB-related service parts

Adj/set/operate method = Select the item, and then press OK key.

Caution = Be sure to close all covers before execution.

Display/adj/set range In processing: ACTIVE, At normal termination: OK, At abnormal termination: NG

Required time Approx. 1 minute

———————————————————————————————————————-

Related service mode/ COPIER> DISPLAY> MISC> ITB-POS

Display of ITB steering reference position

Level.1 Details To display the steering reference position of ITB.

Use case = At initial installation (after execution of COPIER> FUNCTION>MISC-P> ITB-INIT)

Adj/set/operate method = N/A (display only)

Display/adj/set range -580 to 580

Unit = 1 pulse

Appropriate target value -300 to 450

Related service mode COPIER> FUNCTION> MISC-P> ITB-INIT

see attached pdf

**Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

12-12-2013

#9

Technician

- Rep Power

- 28

Re: E0075 0003

[QUOTE=teckat;393590]—————————

your welcome

there are installation procedures that need to be followed on all Canon Printers, sadly not all techs are trained on the products they service—-

the Function below is in the install procedure check for IRADC5051ITB.JPG

COPIER > FUNCTION > MISC-P ITB-INIT

Initial adjustment of ITB Steering

Level.1 =Details To make initial adjustment of reference position for the ITB Steering at initial installation or replacement of the ITB-related service parts.

Use cases — -At installation

—When replacing the ITB-related service parts

Adj/set/operate method = Select the item, and then press OK key.

Caution = Be sure to close all covers before execution.

Display/adj/set range In processing: ACTIVE, At normal termination: OK, At abnormal termination: NG

Required time Approx. 1 minute

———————————————————————————————————————-

Related service mode/ COPIER> DISPLAY> MISC> ITB-POS

Display of ITB steering reference position

Level.1 Details To display the steering reference position of ITB.

Use case = At initial installation (after execution of COPIER> FUNCTION>MISC-P> ITB-INIT)

Adj/set/operate method = N/A (display only)

Display/adj/set range -580 to 580

Unit = 1 pulse

Appropriate target value -300 to 450

Related service mode COPIER> FUNCTION> MISC-P> ITB-INIT

see attached pdf

Hi

my problem

iRAC5235i changed ITB unit for new one ,after ITB init received E 075-003.Counter 102:25000.any idea?

-

12-12-2013

#10

Re: E0075 0003

Is printer level ?

What is reading on display ?**Knowledge is time consuming, exhausting and costly for a trained Tech.**

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

В статье дается краткое описание и расшифровка возможных предупреждений и аварийных сигналов в частотном преобразователе младшей серии VEDA VFD VF 51.

Система самодиагностики преобразователя частоты серии VEDA VFD VF-51 постоянно контролирует состояние питания на входе, состояние выходных сигналов, характеристики двигателя, а также другие рабочие параметры системы. Предупреждение или аварийный сигнал не обязательно означают, что проблема связана с самим преобразователем частоты. Во многих случаях они могут оповещать о сбое, связанном с входным напряжением, нагрузкой или температурой двигателя, внешними сигналами или с другими параметрами, контролируемыми внутренней логикой преобразователя частоты.

Таблица 1. Описание кодов ошибок ПЧ VEDA VFD VF-51

| № |

Код аварии (ошибки, неисправности, Error) и краткое описание |

| 1 | E.SC1 (1) Сбой системы во время разгона |

|---|---|

| 2 | E.SC2 (2) Сбой системы во время торможения |

| 3 | E.SC3 (3) Сбой системы при постоянной скорости |

| 4 | E.SC4 (4) Сбой системы при простое |

| 5 | Е.ОС1 (5) Перегрузка по току при разгоне |

| 6 | Е.ОС2 (6) Перегрузка по току во время торможения |

| 7 | Е.ОС3 (7) Перегрузка по току при постоянной скорости |

| 8 | Е.ОС4 (8) Программная перегрузка по току VF-51 |

| 9 | E. OU1 (9) Перегрузка по напряжению во время разгона |

| 10 | E. OU2 (10) Перегрузка по напряжению во время торможения |

| 11 | E. OU3 (11) Перегрузка по напряжению при постоянной скорости |

| 12 | E.LU (13) Пониженное напряжение |

| 13 | E.OL1 (14) Перегрузка электродвигателя |

| 14 | E.OL2 (15) Перегрузка 1 преобразователя частоты |

| 15 | E.OL3 (16) Перегрузка 2 преобразователя частоты |

| 16 | E.OL4 (17) Перегрузка 3 преобразователя частоты |

| 17 | E.ILF (18) Обрыв фазы на входе преобразователя частоты |

| 18 | E.OLF (19) Обрыв фаз на выходе преобразователя частоты |

| 19 | E.OLF1 (20) Обрыв фазы U |

| 20 | E.OLF2 (21) Обрыв фазы V |

| 21 | E.OLF3 (22) Обрыв фазы W |

| 22 | E.OH1 (30) Перегрев модуля выпрямителя |

| 23 | E.OH2 (31) Перегрев модуля IGBT |

| 24 | E.OH3 (32) Перегрев электродвигателя |

| 25 | E.EF (33) Внешняя ошибка |

| 26 | E.CE (34) Ошибка связи по Modbus |

|---|---|

| 27 | E.HAL1 (35) Смещение ноля фазы U |

| 28 | E.HAL2 (36) Смещение ноля фазы V |

| 29 | E.HAL3 (38) Смещение ноля фазы W |

| 30 | E.HAL (37) Ошибка обнаружения трехфазного тока (сумма токов не равна 0) |

| 31 | E.SGxx (40) Короткое замыкание на землю |

| 32 | E.FSG (41) Короткое замыкание вентилятора |

| 33 | E.PID (42) Обрыв обратной связи ПИД-регулятора |

| 34 | E.COP (43) Ошибка копирования параметров |

| 35 | E.PG01 (44) Ошибка настройки параметров энкодера |

| 36 | E.PG02 (44) Ошибка Z канала энкодера |

| 37 | E.PG03 (44) Ошибка проверки вращения энкодера |

| 38 | E.PG04 (44) Ошибка подключения энкодера |

| 39 | E.PG05 (44) Ошибка ABZ каналов энкодера |

| 40 | E.PG06 (44) Ошибка подключения энкодера шпинделя |

| 41 | E.PG07 (44) Ошибка Z канала энкодера шпинделя |

| 42 | E.PG08 (44) Логическая ошибка Z канала энкодера |

| 43 | E.PG09 (44) Логическая ошибка Z канала энкодера шпинделя |

| 44 | E.PG10 (44) Прерывание импульса Z канала энкодера |

| 45 | E.BRU (50) Ошибка тормозного модуля |

| 46 | E.Texx (52) Превышение выходного тока при автоподстройке |

| 47 | E.IAE1 (71) Ошибка автоподстройки двигателя 1 |

| 48 | E.IAE2 (72) Ошибка автоподстройки двигателя 2 |

| 49 | E.IAE3 (73) Ошибка автоподстройки двигателя 3 |

| 50 | E.PST1 (74) Ошибка автоподстройки синхронного двигателя 1 |

| 51 | E.PST2 (75) Ошибка автоподстройки синхронного двигателя 2 |

| 52 | E.PST3 (76) Ошибка автоподстройки синхронного двигателя 3 |

| 53 | E.DEF (77) Превышение отклонения по скорости |

| 54 | E.SPD (78) Ошибка превышения по скорости |

| 55 | E.LD1 (79) Защита нагрузки 1 |

| 56 | E.LD2 (80) Защита нагрузки 2 |

| 57 | E.CPU (81) Превышение времени ожидания процессора |

| 58 | E.LOC (85) Программное обеспечение |

| 59 | E.EEP (86) Ошибка хранилища параметров |

| 60 | E.BUS1 (91) Карта расширения А отключена |

| 61 | E.BUS2 (92) Карта расширения Б отключена |

| 62 | E.BUS3 (93) Ошибка карты расширения CAN |

| 63 | E.BUS4 (94) Ошибка карты расширения |

| 64 | E.BUS5 (95) Ошибка карты расширения |

| 65 | E.BUS6 (96) Отключение карты расширения |

| 66 | E.CP1 (97) Ошибка компаратора 1 |

| 67 | E.CP2 (98) Ошибка компаратора 2 |

| 68 | E.DAT (99) Ошибка установки параметра |

| 69 | E.FA1 (110) Откказ внешнего расширения 1 |

| 70 | E.FA2 (111) Откказ внешнего расширения 2 |

| 71 | E.FA3 (112) Откказ внешнего расширения 3 |

| 72 | E.FA4 (113) Откказ внешнего расширения 4 |

| 73 | E.FA5 (114) Откказ внешнего расширения 5 |

| 74 | E.FA6 (115) Откказ внешнего расширения 6 |

| 75 | E.FA7 (116) Откказ внешнего расширения 7 |

| 76 | E.FA8 (117) Откказ внешнего расширения 8 |

Аварийный сигнал (существенная неисправность) выводится в случае отключения преобразователя частоты по срабатыванию системы защиты. Двигатель останавливается выбегом. Система управления преобразователем частоты продолжает работать и контролирует состояние цепей управления преобразователя частоты. После того, как причина ошибки будет устранена, код ошибки можно сбросить и преобразователь частоты снова будет готов к работе. Информация о каждом аварийном событии сохраняется в журнале ошибок.

Таблица 2. Коды предупреждения (раннего оповещения) ПЧ VEDA VFD VF-51

| № |

Коды предупреждений ( оповещений, Warning, Alarm) и наименование |

| 1 | A.LU1 (128) Пониженное напряжение во время отключения |

|---|---|

| 2 | A.OU (129) Перенапряжение при отключении |

| 3 | A.ILF (130) Обрыв фазы на входе преобразователя частоты |

| 4 | A.PID (131) Обрыв обратной связи ПИД-регулятора |

| 5 | A.EEP (132) Предупреждение об ошибке в чтении и записи параметров |

| 6 | A.DEF (133) Превышение в отклонении скорости вращения |

| 7 | A.SPD (134) Неверная скорость вращения |

| 8 | A.GPS1 (135) Блокировка GPS |

| 9 | A.GPS2 (136) Обрыв GPS |

| 10 | A.CE (137) Ошибки в работе ModBus |

| 11 | A.LD1 (138) Защита нагрузки 1 |

| 12 | A.LD2 (139) Защита нагрузки 2 |

| 13 | A.BUS (140) Потеря соединения с картой расширения |

| 14 | A.OH1 (141) Перегрев модуля |

| 15 | A.OH3 (142) Перегрев электродвигателя |

| 16 | A.RUN1 (143) Конфликт команд запуска |

| 17 | A.RUN2 (158) Защита от толчкового запуска |

| 18 | A.RUN3 (159) Защита от перезапуска |

| 19 | A.PA2 (144) Потеря соединения с панелью управления |

| 20 | A.COP (145) Ошибка в копировании параметров |

| 21 | A.CP1 (146) Предупреждение о выходном значении компаратора 1 |

| 22 | A.CP2 (147) Предупреждение о выходном значении компаратора 2 |

| 23 | A.FA1 (150) Предупреждение внешнего расширения 1 |

| 24 | A.FA2 (151) Предупреждение внешнего расширения 2 |

| 25 | A.FA3 (152) Предупреждение внешнего расширения 3 |

| 26 | A.FA4 (153) Предупреждение внешнего расширения 4 |

| 27 | A.FA5 (154) Предупреждение внешнего расширения 5 |

| 28 | A.FA6 (155) Предупреждение внешнего расширения 6 |

Предупреждение (несущественная неисправность) выводится при возникновении ненормальных условий работы, вследствие чего преобразователь частоты может выдать сигнал предупреждения. Предупреждение не влияет на работоспособность преобразователя частоты: двигатель продолжает работу, если запущен или его можно запустить, если он остановлен. Предупреждение сбрасывается автоматически при устранении причины.

-

Главная

-

Dennis The Fat Kid

-

Canon IR ADV C50xx / 52 xx Error Code E000075 0003 ITB Belt Askew- How to solve, how to reposition

Просмотров: 17 241

Если вам понравилось бесплатно смотреть видео canon ir adv c50xx / 52 xx error code e000075 0003 itb belt askew- how to solve, how to reposition онлайн которое загрузил Dennis The Fat Kid 16 сентября 2021 длительностью 00 ч 04 мин 34 сек в хорошем качестве, то расскажите об этом видео своим друзьям, ведь его посмотрели 17 241 раз.

Copyright ©

Epicube.su

Смотрите видео на портале epicube.su совершенно бесплатно и без регистрации. Наша видеотека каждый день обновляется лучшими роликами со всего мира!

admin@epicube.su Наша почта для ваших пожеланий и связи с нами.

-

-

Points to Note When Clearing MN-CON

349

-

Points to Note When Clearing HDD

349

-

-

E001-0001-05 Fixing Main Thermistor High Temperature Detection Error

350

-

E001-0002-05 Fixing Sub Thermistor (Front) High Temperature Detection Error

350

-

E001-0003-05 Fixing Sub Thermistor (Rear) High Temperature Detection Error

350

-

E001-0004-05 Fixing Main Thermistor High Temperature Detection Error

351

-

E001-0005-05 Fixing Sub Thermistor (Front) High Temperature Detection Error

351

-

E001-0006-05 Fixing Sub Thermistor (Rear) High Temperature Detection Error

351

-

E002-0001-05 Fixing Main Thermistor Temperature Increase Detection Error

352

-

E002-0002-05 Fixing Main Thermistor Open Circuit Detection Error

352

-

E002-0003-05 Fixing Sub Thermistor (Front) Open Circuit Detection Error

352

-

E002-0004-05 Fixing Sub Thermistor (Rear) Open Circuit Detection Error

353

-

E003-0004-05 Fixing Main Thermistor Low Temperature Detection Error

353

-

E003-0005-05 Fixing Sub Thermistor (Front) Low Temperature Detection Error

353

-

E003-0006-05 Fixing Sub Thermistor (Rear) Low Temperature Detection Error

354

-

E004-0001-05 Fixing Relay Welding Detection Error

354

-

E004-0002-05 Current Detection Circuit Error

354

-

E009-0000-05 Fixing Pressure Timeout Error

355

-

E009-0001-05 Fixing Disengagement Timeout Error

355

-

E010-0001-05: Bk Drum_Itb Motor Error

356

-

E010-0002-05: Bk Drum_Itb Motor Error

356

-

E010-0003-05: Bk Drum_Itb Motor Error

357

-

E012-0001-05: CL Drum Motor Error

357

-

E012-0002-05: CL Drum Motor Error

358

-

E012-0003-05: CL Drum Motor Error

358

-

E013-0001-05: Waste Toner Feed Motor Error

359

-

E014-0001-05: Fixing Motor Error

359

-

-

E014-0002-05: Fixing Motor Error

360

-

E014-0003-05: Fixing Motor Error

360

-

E020-01A8-05: Toner Density Sensor (Y) Output Error

361

-

E020-01B8-05: Toner Density Sensor (Y) Output Error

362

-

E020-01C8-05: Error in Take-Up of Sealing Member (Y)

363

-

E020-02A8-05: Toner Density Sensor (M) Output Error

364

-

E020-02B8-05: Toner Density Sensor (M) Output Error

365

-

E020-02C8-05: Error in Take-Up of Sealing Member (M)

366

-

E020-03A8-05: Toner Density Sensor (C) Output Error

367

-

E020-03B8-05: Toner Density Sensor (C) Output Error

368

-

E020-03C8-05: Error in Take-Up of Sealing Member (C)

369

-

E020-04A8-05: Toner Density Sensor (Bk) Output Error

370

-

E020-04B8-05: Toner Density Sensor (Bk) Output Error

371

-

E020-04C8-05: Error in Take-Up of Sealing Member (Bk)

372

-

E021-0001-05: Developing Motor Error

373

-

E021-0002-05: Developing Motor Error

373

-

E021-0120-05 Developing Screw Rotation Detection Error (Y)

374

-

E021-0220-05 Developing Screw Rotation Detection Error (M)

374

-

E021-0320-05 Developing Screw Rotation Detection Error (C)

374

-

E021-0420-05 Developing Screw Rotation Detection Error (Bk)

375

-

E025-0110-05 Bottle Motor Error (Y)

375

-

E025-0120-05 Bottle Motor Error (Y)

375

-

E025-0168-05: no Toner Detection Error (Y)

376

-

E025-0210-05: Bottle Motor Error (M)

376

-

E025-0220-05 Bottle Motor Error (M)

377

-

E025-0268-05 no Toner Detection Error (M)

377

-

E025-0310-05 Bottle Motor Error (C)

378

-

E025-0320-05 Bottle Motor Error (C)

378

-

E025-0368-05: no Toner Detection Error (C)

379

-

E025-0410-05: Bottle Motor Error (Bk)

379

-

E025-0420-05 Bottle Motor Error (Bk)

380

-

E025-0468-05 no Toner Detection Error (Bk)

380

-

E029-5008-05: Registration Patch Sensor (Front) Density Error

381

-

E029-7008-05 Registration Patch Sensor (Rear) Density Error

382

-

E064-1101-05 High Voltage Error

382

-

E064-1103-05 High Voltage Error

383

-

E064-1201-05 High Voltage Error

383

-

E064-1203-05 High Voltage Error

384

-

E064-1301-05 High Voltage Error

384

-

E064-1303-05 High Voltage Error

385

-

E064-1401-05 High Voltage Error

385

-

E064-1403-05 High Voltage Error

386

-

E073-0001-05 Interlock Error

386

-

E074-0001-05: ITB HP Time out Error

387

-

E074-0002-05: ITB HP Time out Error

388

-

E100-0001-05 BD Error

389

-

E110-0001-05 Scanner Motor Error

389

-

E110-0002-05 Scanner Motor Error

389

-

E110-0003-05 Scanner Motor Error

389

-

E110-0004-05 Scanner Motor Error

390

-

E193-0001-05 Communication Error

390

-

E196-0000-05 Communication Error

390

-

E196-0001-05 Communication Error

390

-

E196-000F-05 Communication Error

391

-

E196-0100-05 Communication Error

391

-

E196-0101-05 Communication Error

391

-

E196-010F-05 Communication Error

391

-

E196-0800-05 Communication Error

392

-

E196-0801-05 Communication Error

392

-

E196-080F-05 Communication Error

392

-

E197-0B11-05 Serial Communication Error

393

-

E197-0B20-05 Serial Communication Error

393

-

E197-0B21-05 Serial Communication Error

393

-

E197-1001-05 Serial Communication Error

393

-

E197-1002-05 Serial Communication Error

394

-

E197-1004-05 Serial Communication Error

394

-

E197-1081-05 Serial Communication Error

394

-

E197-1082-05 Serial Communication Error

394

-

E197-1084-05 Serial Communication Error

395

-

E197-5000-05 Serial Communication Error

395

-

E197-5001-05 Serial Communication Error

395

-

E199-0101-05 Error in High Voltage Sequence (Y)

396

-

E199-0102-05 Error in High Voltage Sequence (M)

396

-

E199-0103-05 Error in High Voltage Sequence (C)

396

-

E199-0201-05 Error in High Voltage Sequence (Y)

396

-

E199-0202-05 Error in High Voltage Sequence (M)

396

-

E199-0203-05 Error in High Voltage Sequence (C)

396

-

E199-0204-05 Error in High Voltage Sequence (K)

396

-

E202-0001-04 Reader Scanner Unit HP Error

396

-

E202-0002-04 Reader Scanner Unit HP Error

397

-

E202-0003-04 Reader Scanner Unit HP Error

397

-

E202-0004-04 Reader Scanner Unit HP Error

397

-

E202-0010-04 Reader Scanner Unit HP Error

397

-

E202-0101-04 DADF Scanner Unit HP Error

398

-

E202-0102-04 DADF Scanner Unit HP Error

398

-

E227-0001-04 Power Supply Error

398

-

E227-0101-04 Power Supply Error

398

-

E240-0002-00 Controller Communication Error

399

-

E240-0005-00 Controller Communication Error

399

-

E240-0D00-00 Controller Communication Error

400

-

E246-0001-00 System Error

400

-

E246-0002-00 System Error

400

-

E246-0003-00 System Error

400

-

E246-0005-00 System Error

400

-

E247-0001-00 System Error

400

-

E247-0002-00 System Error

400

-

E247-0003-00 System Error

400

-

E247-0004-00 System Error

400

-

E248-0001-04 EEPROM Error

401

-

E248-0002-04 EEPROM Error

401

-

E248-0003-04 EEPROM Error

401

-

E248-0010-04 EEPROM Error

401

-

E248-0102-04 EEPROM Error

401

-

E248-0103-04 EEPROM Error

402

-

E260-0001-05 Power Supply Error

402

-

E260-0002-05 Power Supply Error

402

-

E280-0001-04 Communication Error

402

-

E280-0002-04 Communication Error

403

-

E280-0101-04 Communication Error

403

-

E280-0102-04 Communication Error

403

-

E302-0001-04 Error in Paper Front White Shading

403

-

E302-0002-04 Error in Paper Front Black Shading

404

-

E302-0003-04 Error in Paper Front White Shading

404

-

E302-0101-04 Error in Paper Back White Shading

404

-

E302-0102-04 Error in Paper Back Black Shading

404

-

E302-0103-04 Error in Paper Back White Shading

405

-

E315-0007-00 Image Process Device Timeout Error

405

-

E315-000D-00 Image Process Device Timeout Error

405

-

E315-0027-00 Image Process Device Timeout Error

405

-

E315-0035-00 Image Process Device Timeout Error

405

-

E315-0500-00 Image Process Device Timeout Error

406

-

E315-0510-00 Image Process Device Timeout Error

406

-

E315-0530-00 Image Process Device Error

406

-

E315-0531-00 Image Process Device Timeout Error

406

-

E315-0540-00 Image Process Device Error

406

-

E315-0541-00 Image Process Device Timeout Error

407

-

E350-0000-00 System Error

407

-

E350-0001-00 System Error

407

-

E350-0002-00 System Error

407

-

E350-0003-00 System Error

407

-

E350-3000-00 System Error

407

-

E351-0000-00 System Error

407

-

E354-0001-00 System Error

407

-

E354-0002-00 System Error

407

-

E355-0001-00 System Error

407

-

E355-0004-00 System Error

408

-

E400-0001-04 Communication Error

408

-

E400-0002-04 Communication Error

408

-

E400-0003-04 Communication Error

408

-

E412-0005-04 Fan Error

408

-

E412-0006-04 Fan Error

408

-

E423-0001-04 SDRAM Error in the Main Controller PCB

409

-

E423-0002-04 SDRAM Error in the Main Controller PCB

409

-

E490-0001-04 Different Scanner Unit Model Error

409

-

E490-0002-04 Different Scanner Unit Model Error

409

-

E490-0101-04 Different DADF Model Error

409

-

E490-0102-04 Different DADF Model Error

409

-

E490-9999-04 Error Due to the Reader for Different Model

410

-

E500-0000-02 Communication Error (Finisher-K1/Sorter-A1)

410

-

E501-0000-02 Communication Error (Finisher-AA1)

410

-

E503-0021-02 Error in Communication between the Finisher and Saddle Unit (Finisher-AA1)

411

-

E503-0022-02 Error in Communication between the Finisher and Saddle Unit (Finisher-AA1)

411

-

E503-0031-02 Error in Communication between the Finisher and Puncher Unit (Finisher-AA1)

411

-

E503-0032-02 Error in Communication between the Finisher and Puncher Unit (Finisher-AA1)

412

-

E503-0041-02 Error in Communication between the Finisher and Buffer Pass (Finisher-AA1)

412

-

E503-0042-02 Error in Communication between the Finisher and Buffer Pass (Finisher-AA1)

412

-

E503-0061-02 Error in Communication between the IC of Finisher Controller PCB (Finisher-AA1)

412

-

E503-0062-02 Error in Communication between the IC of Finisher Controller PCB (Finisher-AA1)

413

-

E505-0001-02 Error in EEPROM of the Finisher (Finisher-K1/Finisher-Aa1/Sorter-A1)

413

-

E505-0004-02 Puncher Unit Data Error (Puncher Unit-A1)

413

-

E505-0005-02 Buffer Pass Data Error (Finisher-AA1)

413

-

E514-0002-02 Assist Motor Error (Finisher-K1)

413

-

E514-8001-02: A. Assist Motor Error (Finisher-K1) B. Rear End Assist Guide HP Error (Finisher-AA1)

414

-

E514-8002-02 Error in the Paper End Assist Motor (Finisher-AA1)

414

-

E516-0001-02 Paddle Motor Error (Finisher-K1)

414

-

E516-0002-02 Paddle Motor Error (Finisher-K1)

415

-

E530-8001-02: A. Rear Alignment Motor Error (Finisher-K1) B. Front Aligning Plate HP Error (Finisher-AA1)

415

-

E530-8002-02: A. Rear Alignment Motor Error (Finisher-K1) B. Front Aligning Plate HP Error (Finisher-AA1)

416

-

E531-8001-02: A. Stapler Motor Error (Finisher-K1) B. Staple HP Error (Finisher-AA1)

416

-

E531-8002-02: A. Stapler Motor Error (Finisher-K1) B. Staple HP Error (Finisher-AA1)

417

-

E532-8001-02: A. Stapler Shift Motor Error (Finisher-K1) B. Stapler Shift HP Error (Finisher-AA1)

417

-

E532-8002-02: A. Stapler Shift Motor Error (Finisher-K1) B. Stapler Shift HP Error (Finisher-AA1)

418

-

E535-0001-02 Return Belt Motor Error (Finisher-K1)

418

-

E535-0002-02 Return Belt Motor Error (Finisher-K1)

418

-

E535-8001-02 Error in the Swing Guide Motor (Finisher-AA1)

419

-

E535-8002-02: Error in the Swing Guide Motor (Finisher-AA1)

419

-

E537-8001-02: A. Front Alignment Motor Error (Finisher-K1) B. Rear Aligning Plate HP Error (Finisher-AA1)

420

-

E537-8002-02: A. Front Alignment Motor Error (Finisher-K1) B. Rear Aligning Plate HP Error (Finisher-AA1)

420

-

E540-8001-02: A. Tray Shift Motor Error (Finisher-K1) B. Tray 1 Timeout Error (Finisher-AA1)

421

-

E540-8002-02: A. Tray Shift Motor Error (Finisher-K1) B. Tray 1 Shift Area Error (Finisher-AA1)

421

-

E540-8004-02 Stack Tray Paper Surface Detection Error (Finisher-AA1)

422

-

E551-0003-02 Error in the Cooling Fan (Finisher-AA1)

422

-

E551-0004-02 Error in the Cooling Fan of the Finisher (Finisher-AA1)

422

-

E551-0011-02 Error in the Buffer Pass Power Supply Cooling Fan (Finisher-AA1)

422

-

E551-0012-02 Error in the Buffer Pass Power Supply Cooling Fan (Finisher-AA1)

423

-

E551-0013-02 Error in the Buffer Pass Cooling Fan (Finisher-AA1)

423

-

E551-0014-02 Error in the Buffer Pass Cooling Fan (Finisher-AA1)

423

-

E553-8001-02: A. Error in the Escape Delivery Shift Motor (Finisher-AA1) B. Error in the Sorter Shift Motor (Sorter-A1)

423

-

E553-8002-02: A. Error in the Escape Delivery Shift Motor (Finisher-AA1) B. Error in the Sorter Shift Motor (Sorter-A1)

424

-

E553-8011-02 Error in the Flapper Motor (Finisher-AA1)

424

-

E553-8012-02 Error in the Flapper Motor (Finisher-AA1)

425

-

E553-80F1-02 Error in the Saddle Feed/Paddle Motor (Finisher-AA1)

425

-

E553-80F2-02 Error in the Saddle Feed/Paddle Motor (Finisher-AA1)

425

-

E554-8001-02 Safety Switch on Error (Finisher-AA1)

426

-

E577-0002-02 Paddle Motor Error (Finisher-K1)

426

-

E577-8001-02: A. Paddle Motor Error (Finisher-K1) B. Error in the Stack Delivery/Paddle Motor (Finisher-AA1)

426

-

E577-8002-02 Error in the Stack Delivery/Paddle Motor (Finisher-AA1)

427

-

E578-8001-02 Error in the Return Roller Lift Motor (Finisher-AA1)

427

-

E578-8002-02 Error in the Return Roller Lift Motor (Finisher-AA1)

427

-

E57B-8001-02 Error in the Paper End Pushing Guide Motor (Finisher-AA1)

428

-

E57B-8002-02 Error in the Paper End Pushing Guide Motor (Finisher-AA1)

428

-

E583-8001-02 Error in the Tray Auxiliary Guide Motor (Finisher-AA1)

428

-

E583-8002-02 Error in the Tray Auxiliary Guide Motor (Finisher-AA1)

429

-

E590-8001-02 Error in the Punch Motor (Puncher Unit-A1)

429

-

E590-8002-02 Error in the Punch Motor (Puncher Unit-A1)

430

-

E593-8001-02 Error in the Punch Shift Motor (Puncher Unit-A1)

430

-

E593-8002-02 Error in the Punch Shift Motor (Puncher Unit-A1)

430

-

E5F0-8001-02 Error in the Saddle Paper End Stopper Motor (Finisher-AA1)

431

-

E5F0-8002-02 Error in the Saddle Paper End Stopper Motor (Finisher-AA1)

431

-

E5F1-8003-02: Saddle Delivery Motor Clock Error (Finisher-AA1)

432

-

E5F3-8001-02: Error in the Saddle Alignment Motor (Finisher-AA1)

432

-

E5F3-8002-02: Error in the Saddle Alignment Motor (Finisher-AA1)

432

-

E5F4-8001-02: Error in the Saddle Stitcher Motor (Finisher-AA1)

433

-

E5F4-8002-02: Error in the Saddle Stitcher Motor (Finisher-AA1)

433

-

E5F6-8001-02: Error in the Saddle Paper Pushing Plate/Folding Motor (Finisher-AA1)

433

-

E5F6-8002-02: Error in the Saddle Paper Pushing Plate/Folding Motor (Finisher-AA1)

434

-

E5F6-8003-02: Saddle Paper Pushing Plate/Folding Motor Clock Error (Finisher-AA1)

434

-

E5F8-8001-02 Error in the Saddle Switching Lever Motor (Finisher-AA1)

435

-

E5F8-8002-02 Error in the Saddle Switching Lever Motor (Finisher-AA1)

435

-

E5FA-8001-02 Error in the Saddle Gripper Motor (Finisher-AA1)

435

-

E5FA-8002-02: Error in the Saddle Gripper Motor (Finisher-AA1)

436

-

E602-0001-00: HDD Error

436

-

E602-0020-00: HDD Error

436

-

E602-0101-00: HDD Error

437

-

E602-0111-00: HDD Error

437

-

E602-0201-00 HDD Error

438

-

E602-0211-00 HDD Error

438

-

E602-0301-00: HDD Error

439

-

E602-0311-00: HDD Error

439

-

E602-0401-00 HDD Error

440

-

E602-0411-00 HDD Error

440

-

E602-0501-00: HDD Error

441

-

E602-0511-00: HDD Error

441

-

E602-0601-00: HDD Error

442

-

E602-0611-00: HDD Error

442

-

E602-0701-00: HDD Error

443

-

E602-0711-00: HDD Error

443

-

E602-0801-00: HDD Error

444

-

E602-0811-00: HDD Error

444

-

E602-0901-00 HDD Error

445

-

E602-0911-00 HDD Error

445

-

E602-1001-00: HDD Error

446

-

E602-1011-00: HDD Error

446

-

E602-1101-00: HDD Error

447

-

E602-1111-00: HDD Error

447

-

E602-1201-00 HDD Error

448

-

E602-1211-00 HDD Error

448

-

E602-1301-00: HDD Error

449

-

E602-1311-00: HDD Error

449

-

E602-1371-00: System Verification Error

449

-

E602-1401-00 HDD Error

450

-

E602-1411-00 HDD Error

450

-

E602-1701-00: HDD Error

451

-

E602-1711-00: HDD Error

451

-

E602-1801-00 HDD Error

452

-

E602-1811-00 HDD Error

452

-

E602-1901-00 HDD Error

453

-

E602-1911-00 HDD Error

453

-

E602-2000-00 HDD Error

454

-

E602-2001-00 HDD Error

454

-

E602-2002-00 HDD Error

454

-

E602-5001-00 Encryption Chip Error

454

-

E602-5002-00 HDD Error

454

-

E602-FF01-00 HDD Error

455

-

E602-FF11-00 HDD Error

455

-

E604-1024-00 Faulty/Insufficient Image Memory

455

-

E604-1536-00 Faulty/Insufficient Image Memory

455

-

E613-0512-00 Faulty/Insufficient Image Memory

456

-

E613-1024-00 Faulty/Insufficient Image Memory

456

-

E613-1536-00 Faulty/Insufficient Image Memory

456

-

E613-2048-00 Memory Error

456

-

E614-0001-00 Flash PCB Error

456

-

E614-0002-00 Flash PCB Error

457

-

E614-0006-00 Flash PCB Error

457

-

E614-0071-00 System Verification Error

457

-

E614-0072-00 System Verification Error

457

-

E614-0073-00 System Verification Error

458

-

E614-0074-00 Start System Verification Function Error

458

-

E614-0101-00 Flash PCB Error

458

-

E614-0111-00 Flash PCB Error

458

-

E614-0201-00 Flash PCB Error

459

-

E614-0211-00 Flash PCB Error

459

-

E614-0301-00 Flash PCB Error

460

-

E614-0311-00 Flash PCB Error

460

-

E614-0401-00 Flash PCB Error

460

-

E614-0411-00 Flash PCB Error

461

-

E614-0501-00 Flash PCB Error

461

-

E614-0511-00: Flash PCB Error

462

-

E614-0601-00: Flash PCB Error

462

-

E614-0611-00: Flash PCB Error

463

-

E614-0701-00: Flash PCB Error

463

-

E614-0711-00: Flash PCB Error

464

-

E614-4000-00: Flash PCB Error

464

-

E614-4001-00 Flash PCB Error

465

-

E614-4002-00 Flash PCB Error

465

-

E614-4003-00 Flash PCB Error

465

-

E614-4010-00: Flash PCB Error

466

-

E614-4011-00: Flash PCB Error

466

-

E614-4012-00: Flash PCB Error

466

-

E614-9000-00: Flash PCB Error

466

-

E614-9001-00: Flash PCB Error

466

-

E614-9002-00: Flash PCB Error

466

-

E614-9003-00: Flash PCB Error

467

-

E614-9004-00: Flash PCB Error

467

-

E614-9005-00: Flash PCB Error

467

-

E614-FF01-00: Flash PCB Error

467

-

E614-FF11-00 Flash PCB Error

468

-

E615-0001-00 Error in Self-Diagnosis of the Encryption Module

468

-

E674-0021-07 Fax Board Communication Error

468

-

E674-0100-07 Fax Board Communication Error

468

-

E713-0010-05: Communication Error

469

-

E713-0011-05: Communication Error

469

-

E713-0020-05: Communication Error

470

-

E713-0021-05: Communication Error

470

-

E713-0022-05: Communication Error

471

-

E713-0030-05: Communication Error

471

-

E719-0001-00 Error in Coin Vendor

472

-

E719-0002-00 Error in Coin Vendor

472

-

E719-0003-00 Error in Coin Vendor

472

-

E719-0004-00 Coin Vendor Error

472

-

E719-0031-00 Error in Serial Communication at the Start of the New Card Reader

472

-

E719-0032-00 Error in Serial Communication at the Start of the New Card Reader

472

-

E719-0041-00 Coin Vendor Error

472

-

E719-0042-00 Coin Vendor Error

473

-

E720-0001-00 Error Due to Non-Compatible Finisher

473

-

E720-0001-05 Error Due to Non-Compatible Finisher

473

-

E730-C001-00 Error in HDD Access

473

-

E732-0001-04 Communication Error

473

-

E732-0010-00 Communication Error

473

-

E732-0020-00 Communication Error

474

-

E732-0021-00 Communication Error

474

-

E732-0022-00 Communication Error

474

-

E732-0023-04 Communication Error

474

-

E732-0F01-04 Communication Error

474

-

E732-0F20-00 Communication Error

474

-

E732-0F21-00 Communication Error

474

-

E732-0F22-00 Communication Error

474

-

E732-0F23-04 Communication Error

475

-

E733-0000-05 Printer Communication Error

475

-

E733-0001-05 Printer Communication Error

475

-

E733-0002-05 Printer Communication Error

475

-

E733-0F00-05 Printer Communication Error

476

-

E733-0F01-05 Printer Communication Error

476

-

E733-0F02-05 Printer Communication Error

476

-

E733-F000-05 Printer Communication Error

476

-

E733-F001-05 Printer Communication Error

476

-

E733-F002-05 Printer Communication Error

476

-

E743-0000-04 Communication Error

476

-

E743-0001-04 DDI Communication Error

476

-

E744-0001-00 Language File Error

476

-

E744-0003-00 Language File Error

477

-

E744-0004-00 Language File Error

477

-

E744-2000-00 Controller Firmware Mismatch

477

-

E744-4000-05 Error Due to the DC Controller PCB Not Compatible with the Model

477

-

E744-5000-07 Mismatch of Software Version for Fax

477

-

E746-0021-00 Image Analysis Board Error

477

-

E746-0022-00 Image Analysis Board Error

477

-

E746-0023-00 Image Analysis Board Error

477

-

E746-0024-00 Image Analysis Board Error

477

-

E746-0031-00 TPM Error

478

-

E746-0032-00 TPM Error

478

-

E746-0033-00 TPM Error

478

-

E746-0034-00 TPM Auto Recovery Error

478

-

E746-0035-00 TPM Version Error

478

-

E748-2000-00 Main Controller PCB Access Error

479

-

E748-2001-00 Main Controller PCB Access Error

479

-

E748-2010-00 Flash PCB Error / HDD Error

479

-

E748-2011-00 Flash PCB Error

479

-

E748-2012-00 Flash PCB Error

479

-

E748-2021-00 Main Controller PCB Access Error

479

-

E748-2023-00 Main Controller PCB Access Error

480

-

E748-2024-00 Main Controller PCB Access Error

480

-

E748-2025-00 Main Controller PCB Access Error

480

-

E748-2026-00 Main Controller PCB Access Error

480

-

E748-4910-00 Main Controller PCB Access Error

480

-

E748-7011-00 Start System Verification Function Error

480

-

E748-7021-00 Start System Verification Function Error

481

-

E748-7022-00 Start System Verification Function Error

481

-

E748-9000-00 System Error

481

-

E749-0008-00 Error Due to the DC Controller Not Compatible with the Model

481

-

E753-0001-00 Download Error

481

-

E760-0001-00 Main Controller PCB Internal Error

481

-

E804-0000-00 Power Supply Cooling Fan Error

481

-

E806-0100-05 Front Fan Error

482

-

E806-0101-05 Front Fan Error

482

-

E806-0200-05 Motor Fan Error

482

-

E806-0201-05 Motor Fan Error

482

-

E808-0001-05 Zero Cross Signal Detection Error

483

-

E808-0002-05 Zero Cross Signal Detection Error

483

-

E811-0000-05 Fuse in the Fixing Fuse PCB Blowout Error

483

-

E880-0001-00 Controller Fan Error

483

-

E880-0003-00 Controller Fan Error

484

-

E880-0005-00 Error in Controller Fan

484

-

E881-0001-00 Board over Heat Error

484

-

E882-0001-05 Main Power Supply Switch Error

484

-

E890-0001-05 Temperature Detection Error

484

-

E890-0002-05 Temperature Detection Error

485

-

E890-0003-05 Temperature Detection Error

485

-

E996-0071-04 Error for Collecting Sequence Jam Log (ADF)

485

-

E996-0CA1-05 Error for Collecting Sequence Jam Log (Printer)

485

-

E996-0CA2-05 Error for Collecting Sequence Jam Log (Printer)

485

-

E996-0CA3-05 Error for Collecting Sequence Jam Log (Printer)

486

-

E996-0CA4-05 Error for Collecting Sequence Jam Log (Printer)

486

-

E996-0CA5-05 Error for Collecting Sequence Jam Log (Printer)

486

-

E996-0CA6-05 Error for Collecting Log (Printer)

486

-

E996-0CA7-05 Error for Collecting Sequence Jam Log (Printer)

486

-

E996-0CA8-05 Error for Collecting Sequence Jam Log (Printer)

486

-

E996-0CA9-05 Error for Collecting Sequence Jam Log (Printer)

486

-

E996-0CAA-05 Error for Collecting Sequence Jam Log (Printer)

486

-

E996-0CAB-05 Error for Collecting Sequence Jam Log (Printer)

486

-

E996-0CAC-05 Error for Collecting Sequence Jam Log (Printer)

487

-

E996-0CAE-05 Error for Collecting Sequence Jam Log (Printer)

487

-

E996-0CAF-05 Error for Collecting Sequence Jam Log (Finisher)

487

-

E996-0CB0-05 Error for Collecting Sequence Jam Log (Printer)

487

-

E996-0CB3-05 Error for Collecting Sequence Jam Log (Printer)

487

-

E996-0CB4-05 Error for Collecting Sequence Jam Log (Printer)

487

-

E996-0CB6-05 Error for Collecting Log (Printer)

487

-

E996-0CB7-05 Error for Collecting Sequence Jam Log (Printer)

487

-

E996-0CB8-05 Error for Collecting Sequence Jam Log (Printer)

487

-

-

How to View Fax Error Codes

488

-

-

-

Jam Screen Display Specification

540

-

Cassette Feeding Unit-AP1

544

-

2/3 Hole Puncher Unit-A1, 2/4 Hole Puncher Unit-A1, 4 Hole Puncher Unit-A1

548

-

ITB.JPG

ITB.JPG