Всем привет.Вроде бы было все хорошо до прошедшей пятницы.

Поехал по делам в другой город и тут на панели выскочил чек.

Домчал до ближайшего электрика ибо сканер живет в другой машине, а она за много км.

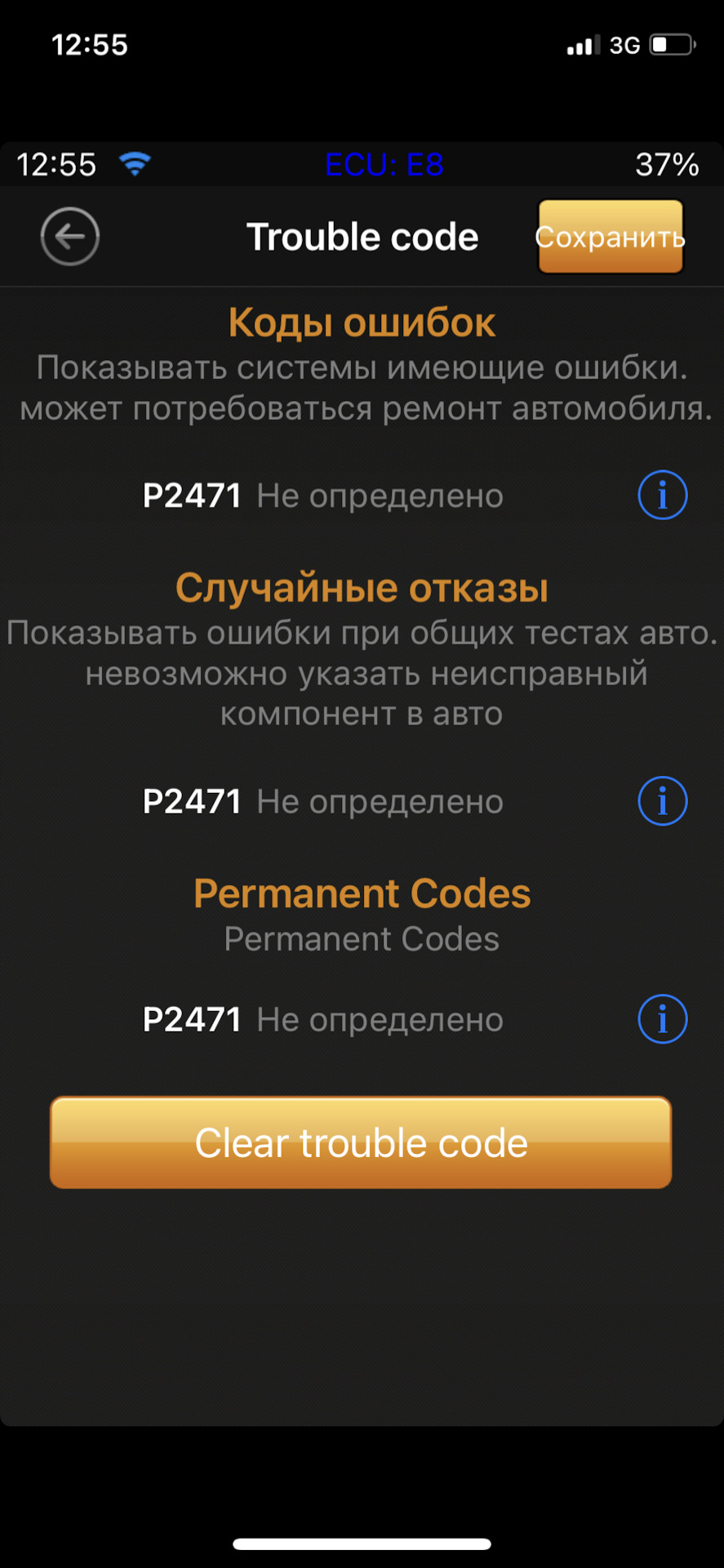

Диагностика показала ошибку P2471 ошибка датчика температуры выхлопных газов.

Времени разбираться не было, ошибку просто скинули.

Вылезла она вновь в субботу уже определил своим сканером.

Перечень причин неисправности интернет пишет весьма обширный от датчика до трещины выхлопной системы.Докатил до центра выхлопных систем, все таки датчик.На неделе скатаюсь к брату пусть посмотрит более подробно, целые от контакты и т.д.

А так все давольно таки сложно.

Запчастит знакомых готов привезти новый за 12 тысяч, но ждать два месяца.

Б/у из «нерезиновой» 25 тысяч, хоть после завтра или новый через официалов 50 тысяч но хз когда.

Ну и есть б/у с разборки с машины разобранной за 4 тысячи через 5 дней.На известных площадках продажи автозапчастей этих датчиков вообще нет, либо идут в комплекте с сажевым фильтром, а там совсем другие суммы🤪

Все сводится к тому что если что случись запчастей на данный авто посерьёзнее просто будет не возможно купить, но мы не ищем легких путей, а вариантов замены машины на что то другое тоже не видим.

Цена вопроса: 0 ₽

Пробег: 120 000 км

Всем привет.Вроде бы было все хорошо до прошедшей пятницы.

Поехал по делам в другой город и тут на панели выскочил чек.

Домчал до ближайшего электрика ибо сканер живет в другой машине, а она за много км.

Диагностика показала ошибку P2471 ошибка датчика температуры выхлопных газов.

Времени разбираться не было, ошибку просто скинули.

Вылезла она вновь в субботу уже определил своим сканером.

Перечень причин неисправности интернет пишет весьма обширный от датчика до трещины выхлопной системы.Докатил до центра выхлопных систем, все таки датчик.На неделе скатаюсь к брату пусть посмотрит более подробно, целые от контакты и т.д.

А так все давольно таки сложно.

Запчастит знакомых готов привезти новый за 12 тысяч, но ждать два месяца.

Б/у из «нерезиновой» 25 тысяч, хоть после завтра или новый через официалов 50 тысяч но хз когда.

Ну и есть б/у с разборки с машины разобранной за 4 тысячи через 5 дней.На известных площадках продажи автозапчастей этих датчиков вообще нет, либо идут в комплекте с сажевым фильтром, а там совсем другие суммы🤪

Все сводится к тому что если что случись запчастей на данный авто посерьёзнее просто будет не возможно купить, но мы не ищем легких путей, а вариантов замены машины на что то другое тоже не видим.

Цена вопроса: 0 ₽

Пробег: 120 000 км

Рассмотрим подробнее

- Техническое описание и расшифровка ошибки P2471

- Симптомы неисправности

- Причины возникновения ошибки

- Как устранить или сбросить код неисправности P2471

- Диагностика и решение проблем

- Проверка датчика и системы EGR

- На каких автомобилях чаще встречается данная проблема

- Видео

Код ошибки P2471 звучит как «высокий уровень сигнала в цепи датчика температуры отработавших газов (Банк 1, Датчик 4)». Часто, в программах, работающих со сканером OBD-2, название может иметь английское написание «Exhaust Gas Temperature (EGT) Sensor Circuit High (Bank 1, Sensor 4)».

Этот диагностический код неисправности (DTC) является общим. Ошибка P2471 считается общим кодом, поскольку применяется ко всем маркам и моделям транспортных средств. Хотя конкретные этапы ремонта могут несколько отличаться в зависимости от модели.

EGR отвечает за рециркуляцию выхлопных газов. Он является частью системы выброса выхлопных газов автомобиля. Используется для снижения температуры, давления сгорания, а также для контроля оксидов азота.

Функция датчика температуры отработавших газов состоит в том, чтобы контролировать температуру в системе рециркуляции. И соответствующим образом регулировать поток с помощью клапана рециркуляции отработавших газов. Который построен на основе обычного термочувствительного датчика резисторного типа.

Чем выше температура выхлопных газов, тем меньше сопротивление относительно земли, что приводит к повышению напряжения. И наоборот, чем ниже температура, тем больше сопротивление, что приводит к снижению напряжения.

Если PCM обнаруживает изменение напряжение, компьютер изменяет фазы газораспределения или соотношение топлива. Чтобы поддерживать температуру в пределах допустимого диапазона внутри преобразователя.

В дизельных двигателях показатель от датчика температуры отработавших газов используется для определения времени регенерации сажевого фильтра.

Когда модуль управления трансмиссией (PCM) обнаруживает высокий уровень сигнала в цепи датчика температуры отработавших газов (Банк 1, Датчик 4). Код неисправности P2471 будет записан в память, а также появится сообщение о ошибке на панели управления.

Симптомы неисправности

Основным симптомом появления ошибки P2471 для водителя является подсветка MIL (индикатор неисправности). Также его называют Check engine или просто «горит чек».

Также они могут проявляться как:

- Загорится контрольная лампа «Check engine» на панели управления (код будет записан в память как неисправность).

- Увеличенный шум двигателя, также может присутствовать звон и дребезжание.

- Увеличение выбросов вредных веществ в выхлопе.

- Чрезмерный запах выхлопных газов.

- Могут быть и другие симптомы.

По технической части, ошибка P2471 не считается серьезной, но в экологическом плане, сильно повышаются выбросы вредных веществ. Однако исправлять проблему необходимо, ведь любая неполадка может привести к более серьезным последствиям.

Причины возникновения ошибки

Код P2471 может означать, что произошла одна или несколько следующих проблем:

- Неисправен датчик температуры отработавших газов.

- Короткое замыкание на землю или внутри датчика температуры отработавших газов.

- Утечка в прокладке датчика температуры системы рециркуляции ОГ.

- Треснувшая или негерметичная выхлопная труба, в которой установлен датчик.

- Жгут проводов или датчик могут быть с повреждениями.

- Провода имеют обрыв или замыкание.

- Поврежденный разъем.

- Послепродажная установка выхлопной системы, которая вызывает проблемы с давлением.

- Прерывистая связь с блоком управления.

- Иногда причиной является неисправный модуль ECM.

Некоторые предлагаемые шаги для устранения неполадок и исправления кода ошибки P2471:

- Очистите коды ошибок и проведите тест-драйв автомобиля, чтобы выяснить появляется ли код P2471 снова.

- Визуально осмотрите датчик температуры отработавших газов и все соответствующие цепи, особенно в местах контакта с горячими компонентами.

- Проверьте соединители на предмет ослабления и наличия коррозии.

- Осмотрите провода на наличие повреждений, которые могут привести к короткому замыканию.

- Проверьте сопротивление датчика температуры отработавших газов с помощью омметра.

- Протестируйте датчик температуры отработавших газов.

- Проверьте наличие утечек в системе.

- Протестируйте модуль ECM и связь с ним.

Диагностика и решение проблем

Сначала необходимо считать все сохраненные данные и коды ошибок с помощью сканера. Затем очистить коды ошибок и провести тест-драйв автомобиля. Чтобы выяснить, появляется ли ошибка P2471 снова.

После этого визуально осмотреть датчик температуры отработавших газов, стоит обратить внимание на утечки выхлопных газов. Также проверить сам датчик и жгут проводов, подходящих к нему. Высокие температуры могут вызвать повреждение проводов с пластмассовой и резиновой изоляцией, поэтому внимательно их проверяйте.

Черная сажа может указывать на утечку выхлопных газов, поэтому внимательно осмотрите места соединений.

Проверка датчика и системы EGR

Многие проблемы с рециркуляцией отработавших газов, вызваны скоплением сажи в выхлопе. Поэтому может быть полезно очистить систему EGR или, по крайней мере, датчик температуры.

После снятия датчика используйте очиститель карбюратора или аналогичный продукт, чтобы эффективно пропитать сажу. С помощью металлической щетки удалите сажу на чрезмерно скопившихся участках. При повторной установке чистого датчика обязательно нанесите на резьбу противозадирный состав, чтобы предотвратить заедание.

Для проверки датчика используйте фен или тепловой пистолет для нагрева, наблюдая за омметром. Сопротивление должно падать при нагревании датчика и повышаться при охлаждении, если этого не происходит, замените его.

Если неисправен сам датчик, для устранения кода P2471 в качестве временной меры можно установить резистор на 2,2 Ом. Просто удалите датчик EGT и подключите резистор к электрическому разъему на стороне двигателя, изолируйте его, и компьютер убедится, что EGT работает правильно.

На каких автомобилях чаще встречается данная проблема

Проблема с кодом P2471 может встречаться на различных машинах, но всегда есть статистика, на каких марках эта ошибка присутствует чаще. Вот список некоторых из них:

- Chevrolet

- Ford

- GMC Sierra

- Hyundai

- Land Rover (Ленд Ровер Рендж Ровер)

- Mercedes

- Mitsubishi (Митсубиси Фусо)

С кодом неисправности Р2471 иногда можно встретить и другие ошибки. Наиболее часто встречаются следующие: P246E, P246F, P2470, P2472.

Видео

Автор:

Virginia Floyd

Дата создания:

6 Август 2021

Дата обновления:

2 Апрель 2023

Содержание

- Возможные причины

- Возможные симптомы

- P2471 Описание

- P2471 Информация для конкретных марок

Возможные причины

Возможные симптомы

P2471 Информация для конкретных марок

Описание P2471 ошибки автомобиля Land Rover. В нашем справочнике имеется следующая информация:

На русском языке:

Датчик 4 температуры отработавших газов, банк 1 — высокий уровень сигнала

На английском языке:

Exhaust Gas Temperature Sensor Circuit High Bank 1 Sensor 4

Выберите модель для возможности более детального просмотра информации по этой ошибке:

Найти причину >>>

Принимая во внимание тот факт, что OBD2 ошибки работы электронных систем автомобиля не всегда на прямую указывают на неработающий элемент, а чаще дают всего лишь общую информацию о неисправности, мы пришли к следующему выводу:

В разных марках и моделях автомобилей одна и также ошибка может возникать как следствие неисправности абсолютно разных элементов.

Стало понятно, что просто необходим ресурс в котором можно найти не только общую информацию об OBD2 ошибке, а практические данные по конкретному автомобилю.

Опыт автоэлектриков показал, что если рассматривать определенную марка-модель автомобиля, то в подавляющем большинстве случаев причина возникновения какой либо ошибки одна и также.

Мы создаем, не без вашей помощи, справочник причинно-следственной связи возникновения той или иной OBD2 ошибки у конкретного автомобиля (марка и модель). Если на Ваш автомобиль не найдено описание (причинно-следственной связи) ошибки, то не стесняйтесь задавайте вопрос.

Если у вас есть опыт в устранении той или иной ошибки — делитесь опытом с другими пользователями. Так мы сможем сформировать полезный ресурс. По капле от каждого и всем будет полезно.

Возможно будет интересно:

Если ошибка указывает на неверные параметры (высокие или низкие значения) какого нибудь из датчиков или анализаторов, то вероятней всего этот элемент исправен, а проблему надо искать так сказать «выше по течению», в элементах работу которых анализирует датчик или зонд.

Если ошибка указывает на постоянно открытый или закрытый клапан, то тут надо подойти к решению вопроса с умом, а не менять бездумно этот элемент. Причин может быть несколько: клапан засорен, клапан заклинил, на клапан приходит неверный сигнал от других неисправных узлов.

Автомобили с каждым днем становятся все более сложными, но и более диагностируемыми. Наш форум создан для всех, от простых автолюбителей до профессиональных автоэлектриков.

То что Вы порвали это CAN шина.

Давление в системе подкачки топлива должно быть 0,5Бар. При езде оно должно колебаться между -0,5 и +0,5 Бар. Регистрирует ошибку когда давление падает ниже -0,7Бар.

U0416-94 Invalid data received from vehicle dynamics control module — unexpected operation

- The terrain response control module has detected that the dynamic response control module component had operated in a way or at a time that it had not been commanded to operate

- The dynamic response system, dynamic response control module is unable to support normal terrain response functionality, the terrain response system will go into default condition

- Dynamic response system fault

- Dynamic response control module failure

Using the manufacturer approved diagnostic system, check the dynamic response control module for DTCs and refer to the relevant DTC index, rectify as required. Check the system is operating correctly and the DTC does not return. Suspect the dynamic response control module, check and install a new dynamic response control module as required, refer to the new module/component installation note at the top of the DTC Index.

Этого должно быть предостаточно что бы решить вашу проблему.

GTR_20405vehicledynamicsuspension.pdf

GTR_20406rideandhandlingoptimization.pdf

GTR_41800modulecommunicationsnetwork.pdf

Изменено 17 октября 2014 пользователем Эгил

|

doituself LR Member Откуда: Питер Авто: Defender Сообщений: 360 Регистрация: 15.10.2010 |

ехал себе спокойно по кольцевой, вдруг вижу: а больше соточки-то деф не разгоняется что это было? Изменено: во всех делах твоих |

|

3WHouse Administrator Откуда: Москва Авто: Defender Сообщений: 6172 Регистрация: 10.09.2010 Land Rover enthusiast! |

было такое, у Кивкова также случалось. That stuff is def .!.. доброе модерирование .!.. |

|

doituself LR Member Откуда: Питер Авто: Defender Сообщений: 360 Регистрация: 15.10.2010 |

виталь, сорри… а что за акция? вроде не прошивал.. во всех делах твоих |

|

3WHouse Administrator Откуда: Москва Авто: Defender Сообщений: 6172 Регистрация: 10.09.2010 Land Rover enthusiast! |

doituself пишет: Прошивка по акции Q068 При движении после холодного пуска двигателя с температурой охлаждающей жидкости That stuff is def .!.. доброе модерирование .!.. |

|

doituself LR Member Откуда: Питер Авто: Defender Сообщений: 360 Регистрация: 15.10.2010 |

так это я могу просто приехать к дилеру и сказать:»эй! делайте мне прошивку по акции Q068! да побыстрее!»? во всех делах твоих |

|

3WHouse Administrator Откуда: Москва Авто: Defender Сообщений: 6172 Регистрация: 10.09.2010 Land Rover enthusiast! |

doituself пишет: если машина гарантийная, то да.. That stuff is def .!.. доброе модерирование .!.. |

|

doituself LR Member Откуда: Питер Авто: Defender Сообщений: 360 Регистрация: 15.10.2010 |

машина-то грантийная… но честно скажу, хоть убей, но мне к ним даже приезжать не хочется((( во всех делах твоих |

|

DIM2 LR User Авто: Defender Сообщений: 54 Регистрация: 08.10.2010 |

На негарантийную машину мне прошили бесплатно. Изменено: |

|

3WHouse Administrator Откуда: Москва Авто: Defender Сообщений: 6172 Регистрация: 10.09.2010 Land Rover enthusiast! |

DIM2 пишет: не-а. есть тема: That stuff is def .!.. доброе модерирование .!.. |

|

master_pj LR User Сообщений: 93 Регистрация: 11.01.2011 |

Помогите советом, куда обратиться. |

|

Piligrimm LR Member Откуда: Санкт-Петербург Регистрация: 29.09.2010 |

Вверху страницы адрес и телефон сервиса. |

|

3WHouse Administrator Откуда: Москва Авто: Defender Сообщений: 6172 Регистрация: 10.09.2010 Land Rover enthusiast! |

что это было?? That stuff is def .!.. доброе модерирование .!.. |

|

master_pj LR User Сообщений: 93 Регистрация: 11.01.2011 |

|

|

tincat80 LR Member Откуда: Москва Авто: Defender Сообщений: 495 Регистрация: 13.10.2010 |

DIM2 пишет:

Изменено: Defender SW 90, 007, Puma 2.4, Stornoway Grey |

|

LRD LR Guest Откуда: Санкт-Петербург Авто: Defender Сообщений: 6 Регистрация: 30.09.2010 |

DIM2 пишет: А дефект так-же был периодическим, или тяга пропала совсем? У меня в выходные на морозе 3 раза был такой эффект. Лечилось перезапуском. Изменено: |

|

LRD LR Guest Откуда: Санкт-Петербург Авто: Defender Сообщений: 6 Регистрация: 30.09.2010 |

Сегодня опять. Температура -18, через 10 минут после начала движения пропала тяга. Остановился, заглушил, завел — все в порядке. Мне кажется, если бы дело было в шланге, то проблема была-бы постоянно. Надо подумать, что происходит при остановке двигателя и запуске? Но похоже, что это старая проблема, акция Q068 ее не исправила, только теперь не выдает ошибок. |

|

DIM2 LR User Авто: Defender Сообщений: 54 Регистрация: 08.10.2010 |

Дырка в патрубке с указательный палец,его немного разорвало давлением,поэтому и изолента не держит. Изменено: |

|

Gam LR Member Откуда: Москва Авто: Defender Сообщений: 128 Регистрация: 01.10.2010 |

LRD пишет: Прошивка Q068 сделана была еще год назад после моей жалобы о пропадании тяги. |

|

3WHouse Administrator Откуда: Москва Авто: Defender Сообщений: 6172 Регистрация: 10.09.2010 Land Rover enthusiast! |

Прошивка Q068 сделана была еще год назад после моей жалобы о пропадании тяги. как мне известно, есть несколько модификаций данной прошивки. That stuff is def .!.. доброе модерирование .!.. |

|

master_pj LR User Сообщений: 93 Регистрация: 11.01.2011 |

#20 01.03.2011 00:45:48 А в домашних условиях прошить мозги возможно? Ну типа купить шнурок USB, прошивку скачать из инета и самому прошить? Я так понял, что сервис на данном сайте успешно решает подобные прблеммы? |

Читают тему (гостей: 1, пользователей: 0, из них скрытых: 0)

Автор:

Virginia Floyd

Дата создания:

6 Август 2021

Дата обновления:

13 Сентябрь 2023

Содержание

- Возможные причины

- Возможные симптомы

- P2471 Описание

- P2471 Информация для конкретных марок

Возможные причины

Возможные симптомы

P2471 Информация для конкретных марок

- The value of the signal measured by the powertrain control module is not plausible given the operating conditions

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module has detected a ground measurement for a period longer than expected or has detected a ground measurement when another value was expected

- Heated oxygen sensor heater circuit short circuit to ground

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module has detected a vehicle power measurement for a period longer than expected or has detected a vehicle power measurement when another value was expected

- Heated oxygen sensor heater circuit short circuit to power

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to power

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module has detected a ground measurement for a period longer than expected or has detected a ground measurement when another value was expected

- Fuel injection related DTCs

- Air induction system leakage

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Check air induction system for leakage

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module has detected a vehicle power measurement for a period longer than expected or has detected a vehicle power measurement when another value was expected

- Fuel injection related DTCs

- Air induction system leakage

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Check air induction system for leakage

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- Fuel injection related DTCs

- Air induction system leakage

- Exhaust gas temperature sensor — Pre catalytic converter circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Pre catalytic converter failure

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Check air induction system for leakage

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Pre catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Pre catalytic converter as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The value of the signal measured by the powertrain control module is not plausible given the operating conditions

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- Other fuel injection related DTCs

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Other fuel injection related DTCs

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

NOTE:

A customer may express a concern that the amber Diesel Particulate Filter (DPF) warning indicator is illuminated on the Instrument Cluster (IC) requesting a DPF regeneration. If the regeneration is not completed the DPF warning indicator will then turn red. The DTCs P2463-00 and P246B-00 will be stored in the Powertrain Control Module (PCM) memory

- The electric throttle air flow characteristics are incompatible with the engine calibration

- The powertrain control module is unable to command a motor, solenoid or relay, to move a piece of equipment to the commanded position either due to a failure in the actuator or its mechanical environment

- Excessive charged air pressure has been measured

- Other related DTCs

- Fuel injection related DTCs

- Exhaust system leakage

- Excessive engine oil level

- Excessive oil in the air induction system

- Air induction system leakage

- Charge air pressure sensor blocked

- Turbocharger system / vanes mechanical integrity

- Electric throttle system / blade mechanical integrity

- Check the powertrain control module for related DTCs and if DTCs P2463-00 and P246B-00 are also logged GO to Pinpoint TestA.

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Check exhaust system for mechanical integrity

- Check and correct the engine oil level

- Check air induction system / turbocharger for failure relating to excessive charged air conditions

- Check air induction system for leakage

- Check air induction system for excessive oil

- Check charge air pressure sensor for blockage

- Check turbocharger system / vanes for mechanical integrity

- Check electric throttle system / blade for mechanical integrity

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Diesel oxidation catalyst exothermic generation capability check. Diesel oxidation catalyst monitoring runs during the active regeneration of the particulate filter. The exhaust gas temperature measured at the catalyst outlet is compared against a model of the expected temperature increase during the active regeneration. A malfunction is reported when the measured temperature is significantly different to this model. The monitoring returns a judgment around 10min after the active particulate filter regeneration was started

- Other related DTCs

- Airpath

- Manifold

- Diesel oxidation catalyst failed, air path failures such as temperature and pressure sensors causing frequent and hot regeneration, any air path failure which will lead to increased soot loading of the DPF such as charge air leak, or blocked air filter causing frequent and hot regeneration

- Exhaust gas temperature sensor — Post catalyst circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Post catalyst failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03F8 Exhaust Gas Temperature Bank2 Sensor 2

- Check powertrain control module for related DTCs and refer to relevant DTC index

- Check and install a new diesel oxidation catalyst (DOC). If the DPF is below the critical soot loading initiate a service regeneration. Confirm soot level reduces correctly. If the DPF is above the critical soot loading replace the DPF and reset the soot loading value

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Post catalyst circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Post catalyst as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

To monitor for too high temperature in the turbine housing; component protection. Temperature sensor temperature above threshold (899.96°C)

- The powertrain control module measured a signal voltage above a specified range but not necessarily a short circuit to power, gain too high

- Other related DTCs

- Airpath

- Turbocharger

- EGR

- Fuel system

- Turbocharger housing mechanical integrity

- Fuel injector (s) mechanical integrity

- Cylinders 1, 2 and 3

- Exhaust gas temperature sensor — Turbine temperature sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Turbine temperature sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x05CA Exhaust Turbine A Inlet Temperature

- Check temperature sensor for plausibility with engine off

- 0x05C9 Exhaust Turbine A Inlet Temperature Sensor Voltage

- Check sensor for voltage plausibility

- Check powertrain control module for related DTCs and refer to relevant DTC index

- Check turbocharger housing for mechanical integrity

- Check fuel injector (s) for mechanical integrity

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Turbine temperature sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module measured a voltage below a specified range but not necessarily a short circuit to ground

- Exhaust gas temperature sensor — Turbine temperature sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Turbine temperature sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x05C9 Exhaust Turbine A Inlet Temperature Sensor Voltage

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Turbine temperature sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module measured a voltage above a specified range but not necessarily a short circuit to power

- Exhaust gas temperature sensor — Turbine temperature sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Turbine temperature sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x05C9 Exhaust Turbine A Inlet Temperature Sensor Voltage

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Turbine temperature sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

SPI communication within heated oxygen sensor internal chip has been disrupted

- Other charged air system related DTCs

- Other fuel system related DTCs

- Air induction system leakage

- EGR system leakage

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Powertrain control module failure

- Check powertrain control module for charged air system related DTCs and refer to relevant DTC index

- Check powertrain control module for fuel system related DTCs and refer to relevant DTC index

- Check air induction system for leakage

- Check EGR system for leakage

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Check and install a new powertrain control module as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- Exhaust system leakage

- Diesel particulate filter degraded

- In cold climates differential pressure sensor hose lines or metal pipes may be frozen

- Differential pressure sensor hoses connected incorrectly

- Differential pressure sensor hoses crushed, blocked, split

- Differential pressure sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Differential pressure sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0xD922 Particulate Filter Differential Pressure — Measured

- Measure with engine off

- Check differential pressure sensor hose lines are not frozen

- Check differential pressure sensor hose lines are installed correctly

- Check differential pressure sensor hose lines for mechanical integrity

- Refer to the electrical circuit diagrams and check the differential pressure sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new differential pressure sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

To monitor for too high temperature at the diesel oxidation catalyst outlet location; DOC/DPF component protection. Temperature sensor temperature above threshold (874.96°C)

- The powertrain control module measured a signal voltage above a specified range but not necessarily a short circuit to power, gain too high

- Overfilled DPF during drop to idle with active DPF regeneration on

- Blocked front face of DPF

- Stuck closed electric throttle butterfly valve during active DPF regeneration

- Other related DTCs

- Airpath

- Turbocharger

- EGR

- Fuel system

- Exhaust gas temperature sensor — Pre catalytic converter circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Pre catalytic converter failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03F7 Exhaust Gas Temperature Bank2 Sensor 1

- 0x03E7 Exhaust Gas Temperature Bank2 Sensor 1 Voltage

- 0x042C Diesel Particulate Filter Soot Concentration

- Check DPF for mechanical integrity

- Check electric throttle butterfly valve for mechanical integrity

- Check powertrain control module for related DTCs and refer to relevant DTC index

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Pre catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Check and install a new exhaust gas temperature sensor — Pre catalytic converter as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Exhaust gas temperature sensor voltage below threshold (80mV)

- The powertrain control module measured a voltage below a specified range but not necessarily a short circuit to ground

- Exhaust gas temperature sensor — Pre catalytic converter circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Pre catalytic converter failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03E7 Exhaust Gas Temperature Bank2 Sensor 1 Voltage

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Pre catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Check and install a new exhaust gas temperature sensor — Pre catalytic converter as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Exhaust gas temperature sensor voltage above threshold (4990mV)

- The powertrain control module measured a voltage above a specified range but not necessarily a short circuit to power

- Exhaust gas temperature sensor — Pre catalytic converter circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Pre catalytic converter failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03E7 Exhaust Gas Temperature Bank2 Sensor 1 Voltage

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Pre catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Check and install a new exhaust gas temperature sensor — Pre catalytic converter as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Exhaust gas temperature sensor — Turbine temperature sensor rationality check. Temperature sensor is checked against other temperature sensors at coldstart

- The powertrain control module detected failure when comparing two or more input parameters for plausibility

- Exhaust gas temperature sensor — Turbine temperature sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Turbine temperature sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x05CA Exhaust Turbine A Inlet Temperature

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Turbine temperature sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Exhaust gas temperature sensor — Turbine temperature sensor rationality check during a driving cycle is not plausible (compared against a temperature model). Exhaust temperature sensor temperature is checked during a vehicle driving cycle against a model temperature for rationality. Some engine speed/load conditions apply. If the difference between the sensor temperature and the model exceeds a defined threshold, a malfunction is raised

- The powertrain control module detected plausibility failures

- Other related DTCs

- Airpath

- Manifold

- Fuel system

- Exhaust gas temperature sensor — Turbine temperature sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Turbine temperature sensor failure

- Check powertrain control module for related DTCs and refer to relevant DTC index

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x05CA Exhaust Turbine A Inlet Temperature

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Turbine temperature sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Exhaust gas temperature sensor temperature at least 50°C above other exhaust gas temperature sensors temperature after 90 minutes engine off time

- The powertrain control module detected failure when comparing two or more input parameters for plausibility

- Exhaust gas temperature sensor — Pre catalytic converter circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Pre catalytic converter failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03F7 Exhaust Gas Temperature Bank2 Sensor 1

- 0x03E7 Exhaust Gas Temperature Bank2 Sensor 1 Voltage

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Pre catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Check and install a new exhaust gas temperature sensor — Pre catalytic converter as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Exhaust gas temperature sensor temperature is checked during a vehicle driving cycle against a model temperature for rationality. Some engine speed/load conditions apply. If the difference between the sensor temperature and the model exceeds a defined threshold, the DTC is set

- The powertrain control module detected plausibility failures

- Exhaust gas temperature sensor — Pre catalytic converter circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Pre catalytic converter failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03F7 Exhaust Gas Temperature Bank2 Sensor 1

- 0x03E7 Exhaust Gas Temperature Bank2 Sensor 1 Voltage

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Pre catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Check and install a new exhaust gas temperature sensor — Pre catalytic converter as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Monitors SCR Nox catalyst efficiency — Reduced catalyst Nox efficiency

- SCR — Reduced catalyst Nox conversion efficiency detected by passive monitoring but not detected by active monitoring; on two consecutive occasions

- The SCR device ammonia storage capability is greatly reduced or the device is missing

- Defective SCR catalyst (aged)

- Deficient DEF reagent delivery

- Diesel exhaust fluid injector partial delivery

- Damaged exhaust metal work

- SCR catalyst damage

NOTE:

Drive vehicle at urban speeds until SCR catalyst warm and exhaust Nox sensors active. Ensure the vehicle is not in DPF active regeneration and drive at urban speeds for 20min (50 / 60mph)

- Check for damaged or removed SCR catalyst

- Check for deposits on front face of SCR catalyst

- Check diesel exhaust fluid injector for deposits or corrosion

- Check exhaust metal work for damage

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Measured oxygen concentration implausibly high compared to model oxygen concentration for Sensor 1 Bank 1, during part load and during low part load

- Other related DTCs

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module has determined failures where some circuit quantity, reported via serial data, is above a specified range

- Other related DTCs

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Measured oxygen concentration implausibly low compared to model oxygen concentration for Sensor 1 Bank 1, during part load and during low part load

- Other related DTCs

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module has determined failures where some circuit quantity, reported via serial data, is below a specified range

- Other related DTCs

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Check powertrain control module for fuel injection related DTCs and refer to relevant DTC index

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module has determined an open circuit via lack of bias voltage, low current flow, no change in the state of an input in response to an output

- Heated oxygen sensor heater circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor heater circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- Other DPF related DTCs

- Diesel particulate substrate is missing — Severely damaged or removed

- DPF failure

NOTE:

Operational requirements needed to allow the monitor to be fully tested. Drive at steady 70mph 6th gear for 10 minutes. Return to workshop and turn engine off, wait 5 minutes, key on and check for DTC

- Check powertrain control module for DPF related DTCs and refer to relevant DTC index

- Remove the DPF and visually inspect for severe damage and correct installation

- Check and install a new DPF as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Measured oxygen concentration implausible compared to other Nox Sensor, bank 1, during part load

- Heated oxygen sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Heated oxygen sensor failure

- Refer to the electrical circuit diagrams and check the heated oxygen sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new heated oxygen sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

To monitor for too high temperature at the diesel oxidation catalyst outlet location; DOC/DPF component protection. Temperature sensor temperature above threshold (874.96°C)

- Electrical Cause

- Yes

- Mechanical Cause

- Yes

- Control Module Cavity

- L319 — Circuit reference I_A_CATTSPOST2

- L494/L405 — Circuit reference CCCOT_B

- TDV8 — Circuit reference CCCOT_A

- The powertrain control module measured a signal voltage above a specified range but not necessarily a short circuit to power, gain too high

- Exhaust gas temperature sensor — Post catalytic converter

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Post catalytic converter failure

- Overfilled DPF during drop to idle with active DPF regeneration on

- Blocked front face of DPF

- Stuck closed electric throttle butterfly valve during active DPF regeneration

- Other related DTCs

- Airpath

- Turbocharger

- EGR

- Fuel system

- Diagnosis of this DTC may require using the Jaguar Land Rover approved diagnostic equipment check datalogger signals

- 0x03F8 Exhaust Gas Temperature Bank2 Sensor 2

- 0x03E9 Exhaust Gas Temperature Bank2 Sensor 2 Voltage

- 0x042C Diesel Particulate Filter Soot Concentration

- 0x061F Exhaust Particulate Filter Soot Mass

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Post catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Post catalytic converter as required

- Check DPF for mechanical integrity

- Check electric throttle butterfly valve for mechanical integrity

- Check powertrain control module for related DTCs and refer to relevant DTC index

- Using the Jaguar Land Rover approved diagnostic equipment, clear the DTCs and retest

NOTE:

Exhaust gas temperature sensor — Post catalytic converter sensor rationality check. Temperature sensor is checked against other temperature sensors at coldstart

- Electrical Cause

- Yes

- Mechanical Cause

- Yes

- Control Module Cavity

- L319 — Circuit reference I_A_CATTSPOST2

- L494/L405 — Circuit reference CCCOT_B

- TDV8 — Circuit reference CCCOT_A

- The powertrain control module detected failure when comparing two or more input parameters for plausibility

- Exhaust gas temperature sensor — Post catalytic converter

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Post catalytic converter failure

- Diagnosis of this DTC may require using the Jaguar Land Rover approved diagnostic equipment check datalogger signals

- 0x03F8 Exhaust Gas Temperature Bank2 Sensor 2

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Post catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Post catalytic converter as required

- Using the Jaguar Land Rover approved diagnostic equipment, clear the DTCs and retest

NOTE:

Exhaust gas temperature sensor — Post catalytic converter sensor rationality check during a driving cycle is not plausible (compared against a temperature model). Exhaust temperature sensor temperature is checked during a vehicle driving cycle against a model temperature for rationality. Some engine speed/load conditions apply. If the difference between the sensor temperature and the model exceeds a defined threshold, a malfunction is raised

- Electrical Cause

- Yes

- Mechanical Cause

- Yes

- Control Module Cavity

- L319 — Circuit reference I_A_CATTSPOST2

- L494/L405 — Circuit reference CCCOT_B

- TDV8 — Circuit reference CCCOT_A

- The powertrain control module detected plausibility failures

- Other related DTCs

- Airpath

- Manifold

- Exhaust gas temperature sensor — Post catalytic converter

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Post catalytic converter failure

- Check powertrain control module for related DTCs and refer to relevant DTC index

- Diagnosis of this DTC may require using the Jaguar Land Rover approved diagnostic equipment check datalogger signals

- 0x03F8 Exhaust Gas Temperature Bank2 Sensor 2

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Post catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Post catalytic converter as required

- Using the Jaguar Land Rover approved diagnostic equipment, clear the DTCs and retest

- Electrical Cause

- Yes

- Mechanical Cause

- Yes

- Control Module Cavity

- L319 — Circuit reference I_A_CATTSPOST2

- L494/L405 — Circuit reference CCCOT_B

- TDV8 — Circuit reference CCCOT_A

- The powertrain control module measured a voltage below a specified range but not necessarily a short circuit to ground

- Exhaust gas temperature sensor — Post catalytic converter circuit short circuit to ground

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Post catalytic converter failure

- Diagnosis of this DTC may require using the Jaguar Land Rover approved diagnostic equipment check datalogger signals

- 0x03E9 Exhaust Gas Temperature Bank2 Sensor 2 Voltage

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Post catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Post catalytic converter as required

- Using the Jaguar Land Rover approved diagnostic equipment, clear the DTCs and retest

- Electrical Cause

- Yes

- Mechanical Cause

- Yes

- Control Module Cavity

- L319 — Circuit reference I_A_CATTSPOST2

- L494/L405 — Circuit reference CCCOT_B

- TDV8 — Circuit reference CCCOT_A

- The powertrain control module measured a voltage above a specified range but not necessarily a short circuit to power

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Exhaust gas temperature sensor — Post catalytic converter circuit short circuit to power, open circuit, high resistance

- Charge air temperature sensor circuit open circuit, high resistance

- Exhaust gas temperature sensor — Post catalytic converter failure

- Charge air temperature sensor failure

- Diagnosis of this DTC may require using the Jaguar Land Rover approved diagnostic equipment check datalogger signals

- 0x03E9 Exhaust Gas Temperature Bank2 Sensor 2 Voltage

- Refer to the electrical circuit diagrams and check the exhaust gas temperature sensor — Post catalytic converter circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new exhaust gas temperature sensor — Post catalytic converter as required

- Using the Jaguar Land Rover approved diagnostic equipment, clear the DTCs and retest

- Diagnostic failure check for minimum pressure differential characteristics

- Diesel particulate filter internal components are missing or destroyed

NOTE:

If this DTC is logged, refer to the relevant pinpoint tests in Section 309-00 (Exhaust System)

- Using the manufacturer approved diagnostic system, check for related DTCs and refer to the relevant DTC index

- Clear DTC and re-test

- Check and install a new diesel particulate filter as required

NOTE:

Differential pressure sensor hoseline mounting check. Differential pressure sensor high pressure hoseline disconnected or differential pressure reading low

- The powertrain control module has detected that the component has been incorrectly installed e.g. hydraulic pipes crossed over, circuits cross wired or polarity errors

- In cold climates differential pressure sensor hose lines or metal pipes may be frozen

- Differential pressure sensor crossed hose lines

- Differential pressure sensor dropped top hose line

- Differential pressure sensor hose lines deteriorated

- Differential pressure sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Differential pressure sensor failure

NOTE:

If this DTC is logged, refer to the relevant pinpoint tests in Section 309-00 (Exhaust System)

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03DB Particulate Filter Differential Pressure Sensor Voltage — Bank 1 — Volts

- Check differential pressure sensor hose lines are not frozen

- Check differential pressure sensor hose lines are installed correctly

- Check differential pressure sensor hose lines for mechanical integrity

- Refer to the electrical circuit diagrams and check the differential pressure sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new differential pressure sensor as required

- Using the manufacturer approved diagnostic system carry out ‘Diesel particulate filter differential pressure sensor replacement’ routine (0x405B_02)

- Using the manufacturer approved diagnostic system clear all stored DTCs using the Diagnosis Menu tab and retest

- Destroyed particulate filter

NOTE:

If this DTC is logged, refer to the relevant pinpoint tests in Section 309-00 (Exhaust System)

- Refer to the relevant pinpoint test in section 309-00

NOTE:

Differential pressure sensor rationality check in afterrun. Differential pressure plausibility check during postdrive in every driving cycle. If the pressure exceeds a defined threshold, (set at 55hPa), the sensor is no longer within specification range

- In cold climates differential pressure sensor hose lines or metal pipes may be frozen

- Differential pressure sensor hoses connected incorrectly

- Differential pressure sensor hoses crushed, blocked, split

- Differential pressure sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Differential pressure sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0xD922 Particulate Filter Differential Pressure — Measured

- Measure with engine off

- Check differential pressure sensor hose lines are not frozen

- Check differential pressure sensor hose lines are installed correctly

- Check differential pressure sensor hose lines for mechanical integrity

- Refer to the electrical circuit diagrams and check the differential pressure sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new differential pressure sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Differential pressure sensor rationality check during exhaust gas flow dynamic conditions. Differential pressure sensor pressure response responds to exhaust gas flow transients

- Other related DTCs

- Contamination in the exhaust system (soot blockage)

- Differential pressure sensor hoses crushed, blocked, split

- Diesel particulate filter system mechanical integrity

- Air intake system leakage

- Differential pressure sensor mechanical integrity

- Differential pressure sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Differential pressure sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signal, 0xD922 Particulate Filter Differential Pressure — Measured

- Check powertrain control module for related DTCs and refer to relevant DTC

- Check exhaust system for contamination (soot blockage)

- Check differential pressure sensor hoses for crushed, blocked, split

- Check DPF system for mechanical integrity

- Check air intake system for mechanical integrity

- Check differential pressure sensor for mechanical integrity

- Refer to the electrical circuit diagrams and check the differential pressure sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new differential pressure sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Differential pressure sensor circuit continuity check. Differential pressure sensor voltage below threshold (80mV)

- The powertrain control module measured a voltage below a specified range but not necessarily a short circuit to ground

- Differential pressure sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Differential pressure sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03DB Particulate Filter Differential Pressure Sensor Voltage — Bank1

- Refer to the electrical circuit diagrams and check the differential pressure sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new differential pressure sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module measured a signal voltage below a specified range but not necessarily a short circuit to ground, gain low

- In cold climates differential pressure sensor hose lines or metal pipes may be frozen

- Differential pressure sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Differential pressure sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0xD922 Particulate Filter Differential Pressure — Measured

- 0x03DB Particulate Filter Differential Pressure Sensor Voltage — Bank 1 — Volts

- Allow thaw if the vehicle was exposed to cold ambient conditions, check DPF differential pressure sensor voltage at key on is above 350mV (DIDx03DB)

- Check differential pressure sensor hose lines for mechanical integrity

- Refer to the electrical circuit diagrams and check the differential pressure sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new differential pressure sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Differential pressure sensor circuit continuity check. Differential pressure sensor voltage above threshold (4990mV)

- The powertrain control module measured a voltage above a specified range but not necessarily a short circuit to power

- Differential pressure sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Differential pressure sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03DB Particulate Filter Differential Pressure Sensor Voltage — Bank1

- Refer to the electrical circuit diagrams and check the differential pressure sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new differential pressure sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

- The powertrain control module measured a signal voltage above a specified range but not necessarily a short circuit to power, gain too high

- In cold climates differential pressure sensor hose lines or metal pipes may be frozen

- Differential pressure sensor circuit short circuit to ground, short circuit to power, open circuit, high resistance

- Connector is disconnected, connector pin is backed out, connector pin corrosion

- Differential pressure sensor failure

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0xD922 Particulate Filter Differential Pressure — Measured

- 0x03DB Particulate Filter Differential Pressure Sensor Voltage — Bank 1 — Volts

- Allow thaw if the vehicle was exposed to cold ambient conditions, check DPF differential pressure sensor voltage at key on is below 800mV (DIDx03DB)

- Check differential pressure sensor hose lines for mechanical integrity

- Refer to the electrical circuit diagrams and check the differential pressure sensor circuit for short circuit to ground, short circuit to power, open circuit, high resistance

- Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

- Check and install a new differential pressure sensor as required

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTE:

Unexpected rapid soot loading of the diesel particulate filter leading to an increased regeneration frequency. Diesel particulate filter soot mass is compared to a maximum soot mass expected during soot loading phases when the diesel particulate filter active regeneration is started. A soot mass higher that the maximum expected soot loading leads to an increased regeneration frequency

- Other related DTCs

- Diesel particulate filter partial blockage

- Charge air system leakage

- Diesel particulate filter is getting full of soot

- Diesel particulate filter hoselines disconnected

- Differential pressure sensor mechanical integrity

- Blocked air filter

- Air intake system leakage

- Exhaust system leakage upstream of diesel particulate filter

- Using the manufacturer approved diagnostic system, check for related DTCs and refer to the relevant DTC index

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system check datalogger signals

- 0x03DB Particulate Filter Differential Pressure Sensor Voltage — Bank 1 — Volts

- Check differential pressure sensor reading (DIDx03DB) is lower than 800mV at ignition on

- 0x05CA Exhaust Turbine A Inlet Temperature

- 0x03F8 Exhaust Gas Temperature Bank2 Sensor 2

- Check charge air system for leakage, split pipework, loose hose clips and damaged hoses

- Check differential pressure sensor for mechanical integrity

- Check air intake system for mechanical integrity

- Check exhaust system upstream of diesel particulate filter for mechanical integrity

- Refer to workshop manual and carry out an on road DPF regeneration drive cycle

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTES:

-

This monitors when the Diesel Particulate Filter (DPF) is full and unable to regenerate

-

A customer may express a concern that the amber Diesel Particulate Filter (DPF) warning indicator is illuminated on the Instrument Cluster (IC) requesting a DPF regeneration. If the regeneration is not completed the DPF warning indicator will then turn red. The DTCs P0234-77 and P246B-00 will be stored in the Powertrain Control Module (PCM) memory

- The electric throttle air flow characteristics are incompatible with the engine calibration

- Other DPF related DTCs

- Diesel particulate filter maximum soot level has been reached

- Charge air system leakage

- Check the powertrain control module for related DTCs and if DTCs P0234-77 and P246B-00 are also logged GO to Pinpoint TestA.

- Diagnosis of this DTC may require using the manufacturer approved diagnostic system to check datalogger signals

- 0x042C Diesel Particulate Filter Soot Concentration

- Using the manufacturer approved diagnostic system carry out a service regeneration procedure

- Check charge air system for leakage, split pipework, loose hose clips and damaged hoses

- Using the manufacturer approved diagnostic system clear all stored DTCs using the ‘Diagnosis Menu’ tab and retest

NOTES:

-

Vehicle needs to be driven in Diesel Particulate Filter (DPF) regeneration conditions. Drive at approximately 70mph in 6th gear for 30min. If 70mph can not be maintained, then keep engine loaded to allow heat to be generated. Regeneration works best under high engine loads. This DTC and Amber message will only be seen if the vehicle has been driven in conditions that DO NOT allow a sufficient regeneration time period and the current soot load is too high

-

A customer may express a concern that the amber Diesel Particulate Filter (DPF) warning indicator is illuminated on the Instrument Cluster (IC) requesting a DPF regeneration. If the regeneration is not completed the DPF warning indicator will then turn red. The DTCs P0234-77 and P246B-00 will be stored in the Powertrain Control Module (PCM) memory

- The electric throttle air flow characteristics are incompatible with the engine calibration

- Diesel particulate filter soot load has crossed an engineering threshold and a regeneration is required to avoid further actions being taken such as a torque limit and a red warning message. This fault will show the amber warning «Exhaust Filter Nearly Full See Handbook» if during the previous ~35 minutes the vehicle has not been driven in conditions that give a successful regeneration

- Diesel particulate filter high soot load. Suitable conditions must be found to allow correct regeneration of the DPF before service action is required

- Continuous diesel particulate filter soot level monitoring ; if the mass exceeds upper limit; the warning is set

- Diesel particulate filter is getting full of soot

- Diesel particulate filter hoselines disconnected

- Differential pressure sensor mechanical integrity

- Blocked air filter

- Air intake system leakage

- Exhaust system leakage upstream of diesel particulate filter

NOTE: